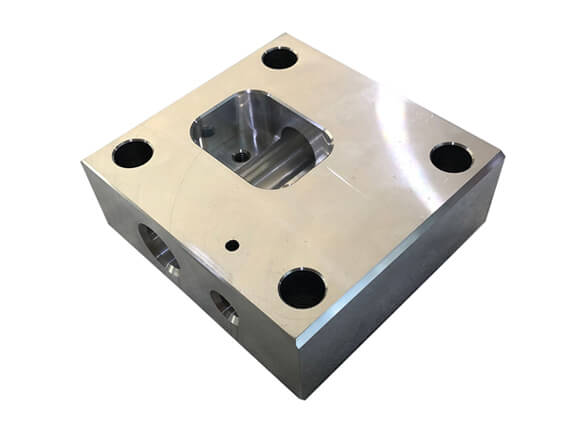

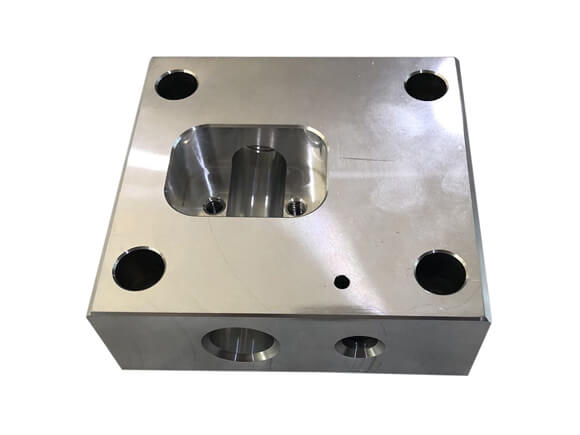

Bộ phận gia công bằng thép không gỉ chính xác của OEM CNC

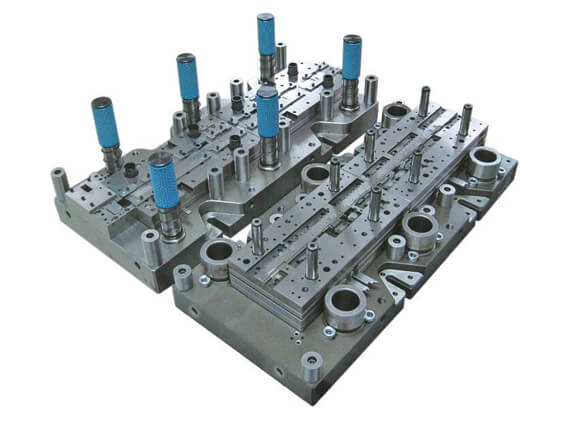

- Dụng cụ trực tiếp

- Tất cả kim loại / hợp kim

- Nhiều trục chính

- +/- 0,0003 "dung sai

- Các hoạt động phay trục Y

Khi bạn cần tiện CNC với độ chính xác cao, hãy nhờ chúng tôi giúp đỡ. Essai cung cấp cho bạn máy tiện CNC chất lượng cao trong nhiều ngành công nghiệp.

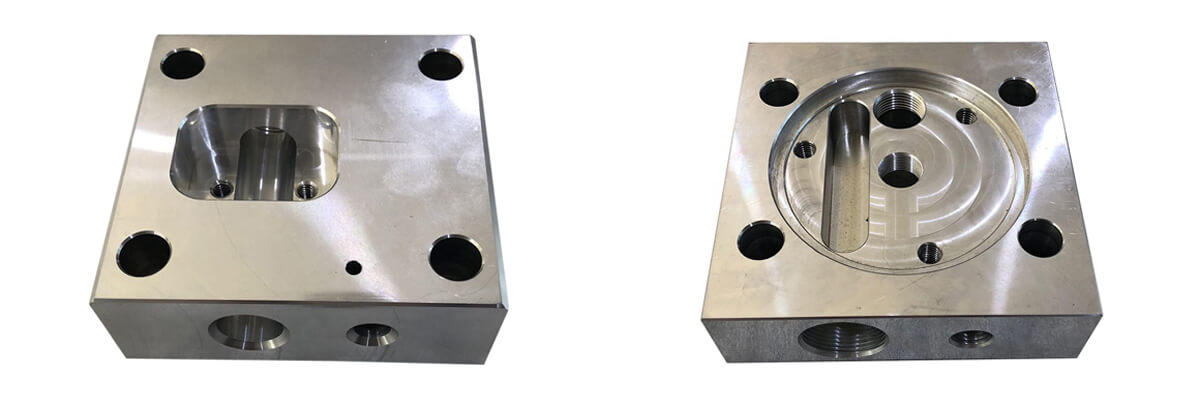

OEM CNC Turning is an intricate and detailed method of creating custom parts and components using a lathe. Computer Numerical Control (CNC) turning is a highly-skilled, Precision Engineering process. Based on one of the oldest machine tools in the world – the lathe – turning in its traditional form can be traced back to ancient Egypt.

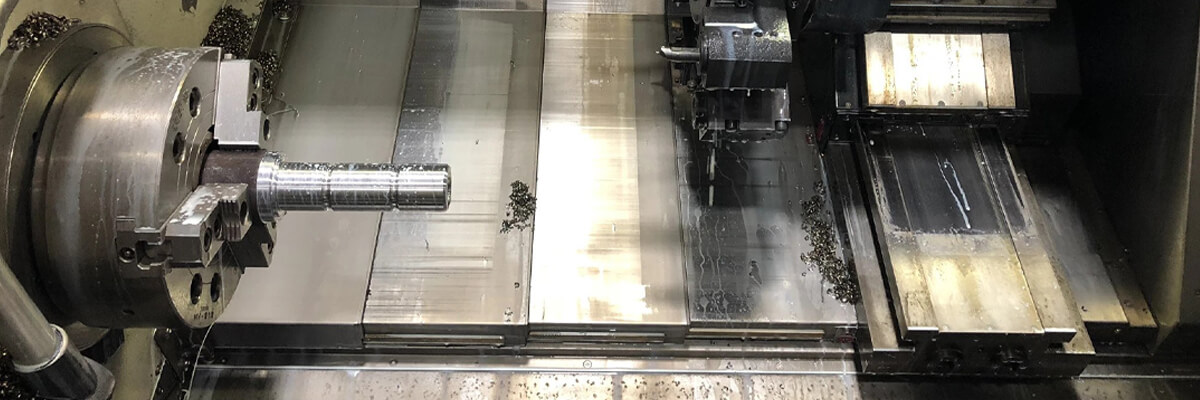

Through modern computer technology and skilled operators, a component can now be created to the minutest detail and to the most rigid of designs using a Turning Lathe, with precise tolerances and a vast array of shapes. The turning lathe secures and rotates the stock, or raw material, being machined along a dual-axis of movement at high speeds, while a single-point cutting or boring tool shapes the material, resulting in the desired component being created. The lathe is controlled by computer programs; ensuring meticulously exact components are produced, and can also be reproduced. At Essai, we pride ourselves on being experts in the latest CNC Turning Technology and Processes, and on our ability to create the components our customers demand swiftly, efficiently and precisely.

Cơ khí CNC

Often turning and milling are generically referred to as “CNC machining” – our customers often ask for CNC machining rather than for turning or milling by name. Of course, it’s our job to make sure that the most appropriate process is used each time.

Put simply, the difference between the two processes comes down to which part moves – in general terms, the metal or the machine.

- With CNC turning a metal bar is fed into the lathe and rotates at speed while a single-point cutting tool removes portions of the metal to create the desired shape.

- With milling, the metal usually remains still while multi-point cutting tools rotate around it.

Applications of OEM CNC Turning

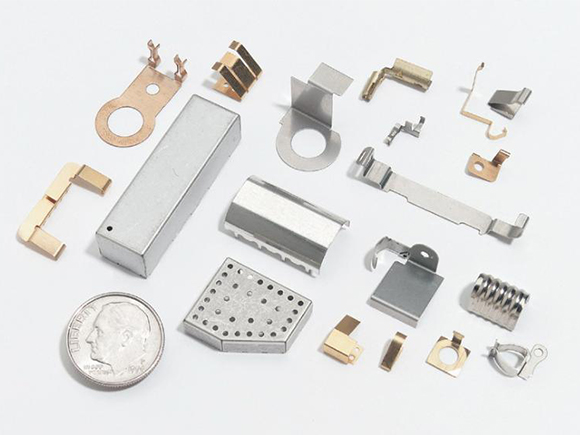

It is widely used in cutting; complex machining; deburring; drilling; vertical machining centers for drilling, boring, tapping and grinding; electrical injection molding; grinding; laser cutting; milling with vertical machining centers; milling; motion control; turning; wire EDM, etc.

| Gia công CNC hay không | Cơ khí CNC |

| Vật chất | Carbon steel, stainless steel, aluminum alloy |

| Process | Turning, Grinding, Milling, etc. |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Unit Weight | 0.1kg~99kg |

| Trang thiết bị | CNC Machining Centers |

| Dịch vụ | Customized OEM |

| Surface Finished | Polishing, zinc plating, nickel plating, chrome plating |

| Inspection | 100% inspection before shipping |

| Chứng chỉ | ISO 9001 |

| Gói | Túi nhựa & thùng carton; Yêu cầu của khách hàng |

Ưu điểm của việc phụ thuộc vào Essai

1. Đúc chết các sản phẩm nhôm được cung cấp với giá cả cạnh tranh.

2. Chúng tôi chuyên về các thành phần hợp kim kim loại nhỏ trong hơn 14 thập kỷ nay.

3. Chúng tôi sử dụng các chuyên gia tốt nhất và kỹ thuật hiện đại để tạo ra hợp kim đúc nhôm và các sản phẩm khác.

4. Chúng tôi cung cấp các dịch vụ trong các ngành đa dạng như phần cứng, máy tính, chăm sóc sức khỏe và ô tô.

5. Sản phẩm của chúng tôi được đảm bảo cung cấp cho bạn một danh tiếng tốt và chúng tôi tuân theo các tiêu chuẩn chất lượng cao.

6. Chúng tôi kiểm tra rộng rãi các sản phẩm.

7. Có thể có nhiều hơn một giải pháp trong tổ chức của chúng tôi.

8. Ý tưởng và thiết kế của bạn sẽ được các chuyên gia của chúng tôi đưa ra một định nghĩa mới.

- +/- 0.0003" tolerance: Typical tolerance, but can vary due to size & type of material.

- Live tooling: Performs up to 12 different CNC milling operations while in the lathe.

- 25" dia x 80" work envelope: Suitable for long or large CNC turning parts and projects.

- Y-axis milling operations: Expands the range of secondary operations, including simultaneous 5-axis milling/turning.

- All metals/alloys: Turn or machine all metals and certain types of plastics.

- Multiple spindle: Turn/mill a complete part in one setup, while maintaining feature relationships.

TRƯỜNG HỢP TƯƠNG TỰ

Cung cấp hỗ trợ phần cứng kỹ thuật cho các doanh nghiệp trong các ngành khác nhau.

Không biết đủ?

Chào mừng bạn đến liên hệ với chúng tôi và bắt đầu kinh doanh của bạn ngay bây giờ!

Văn phòng : No.72-6, Huaanguan South Road, Longhua New District Thâm Quyến, 518110 Trung Quốc

Nhà máy : Số 333 Xiangmang West Road Thị trấn Qingxi, Dongguang, Trung Quốc