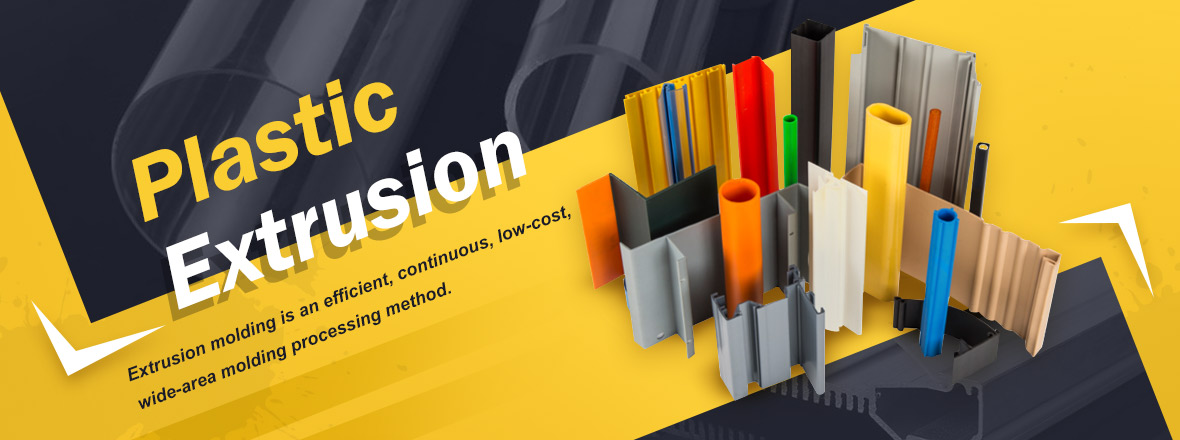

Plastic Extrusion

Plastic Extrusion

Plastic Extrusion molding is an efficient, continuous, low-cost, wide-area molding processing method. It is an earlier technology in polymer material processing. After more than 100 years of development, extrusion molding is a field of polymer processing. The molding processing method with the most varieties, the most changes, high productivity, strong adaptability, wide use, and the largest proportion of output.

Extrusion is one of the most important forms of plastic material processing. The main materials are polyethylene (PE), polypropylene, acetal, acrylic, nylon (polyamide), polystyrene, polyvinyl chloride (PVC), Acrylonitrile butadiene styrene (ABS), polycarbonate, etc. It is suitable for most plastic materials except for some thermosetting plastics, about 50% of thermoplastic products are completed by extrusion molding. At the same time, also It is widely used in the molding of chemical fibers and thermoplastic elastomers and rubber products. Extrusion molding methods can produce various types of continuous products. Such as pipes, rods, sheet materials, profiles, wire and cable coatings, and monofilaments. It can be used for mixing, plasticizing, granulating, coloring and blending modification of polymer materials.

Essai uses a variety of plastic compounds to produce the highest quality plastic extruded products at competitive prices. We have more than ten years of experience and innovative technology in the plastic extrusion industry, which can ensure the provision of high-quality, cost-effective plastic extrusion parts so that your project can be successful. There are some common problems in the production of plastic profiles. Problems, deformation of the profile, bending of the profile, etc. So, how can we avoid these common problems in the profile during the production process?

Plastic profile modification

The existence of internal stress in plastic profiles not only causes bending deformation or cracking of the profiles in use but also affects mechanical properties and apparent quality. Causes of internal stress in plastic profiles:

1. The profile undergoes extrusion and stretching during the molding process. There is unrelaxed high elastic deformation in the orientation of the macromolecules. It is mainly concentrated on the surface layer so that there is large orientation stress in these places, and the orientation is uneven, leading to internal Non-uniform stress.

2. In the cooling stage of the profile, when the temperature is higher than the glass transition temperature, the plastic is a viscoelastic fluid with stress relaxation. When the temperature is lower than the glass transition temperature, the plastic becomes solid, and the curing time and chain. It is difficult to fully adapt between the relaxation speeds of the sections, and the profile after molding will always freeze the internal stress more or less.

3. The wall thickness of the hollow profile is uneven. It is prone to uneven cooling, slow cooling at the thick wall, fast cooling at the thin wall, forming a difference in cooling rate and causing internal stress. The solution: the wall thickness of the profile is as equal and uniform as possible. If it is necessary to have different wall thicknesses. The connection should gradually transition to avoid sudden changes in the section. Cooling at thick walls must be appropriately strengthened in the setting mold.

Bending of plastic profiles

1. The entire production line should be adjusted on a centerline. If it is not on a centerline when the profile passes the dry-type mold into the water tank and finally cools. The profile is artificially bent or distorted. So every time the mold is replaced, it should be squeezed. Out of machine, head, sizing die, accurate correction of concentricity and levelness of tractor.

2. Uneven discharge of the die of the machine head, inconsistent speed is one of the main factors that cause bending. If the flow of the machine head is uneven. We can adjust the surrounding material evenly by blocking and inserting. If the temperature difference between the sides of the machine head is large. The temperature around the die should be adjusted to be consistent.

Specializing in the production of various types of plastic extrusion (squeeze) products. According to customer requirements, develop various molds, produce environmentally friendly and special performance products, use imported raw and auxiliary materials, scientific formulas, and advanced technology to provide reliable quality assurance for products. We have a strong technical force and strong productivity, reliable product quality, and are exported to home and abroad.

1. we fabricated the tool by yourself so that it can reduce the tool cost.

2. Accept your MOQ at inital development.

3. High technology in plastic extrusion.

4. Good sevice from begining to ending and aftersales.

5. Good quality by virgin material and strict quality control.

6. The wear-resistant material can be customized by drawing or sample mold opening

Including PVC profiles, PP, PE, TPE profiles, ABS profiles, PMMA lampshade profiles, acrylic lens extrusions, LED PC profiles, two-color extrusion profiles, various slide rails, circuit guide rails and other engineering plastics, such as pvc / upvc / hdpe / pp / abs.

Welcome To Start Your Business Now!

Contact Us