Rapid prototyping manufacturer ideas 2020: What is rapid cnc machining & 3d printing?

2020-07-20Three important aspects of Rapid prototyping methods and techniques

Prototyping consists in giving substance to an idea, with a view to trying it out in order to observe its functioning, in order to ultimately validate its design.

Rapid prototyping manufacturer are essential in the world of industry. These models resulting from research are the basis of great achievements.

Most products, especially those from technology, have been prototype. The old techniques, requiring the use of traditional methods, are rare now. The evolution and diversification of technology has enabled the innovation of rapid prototyping manufacturer.

What is rapid prototyping? Rapid prototyping manufacturer

This technique amounts to creating a prototype from a digital file, more precisely from a CAD model. The actual representation of this object can flow using different techniques. Such as:

- 3D printing

- CNC machining and

- Thermoforming which execute its shaping.

These Rapid prototyping manufacturer methods make it possible to quickly obtain the desired prototype. It comes with perfect precision and undeniable quality, for a relatively low cost compared to conventional methods.

This high-speed design gives the opportunity to rectify the model within a short time. Moreover, it proceeds without delay to its validation, or even to the production of the part.

What is a prototype?

A prototype designates the first, or one of the first copies of an industrial product.

Rapid Prototyping means all the techniques that allow the production by machines of models from CAD files in a very short time.

This goes as far as:

- Foundry

- Plastics

- Machining

- Tooling

- Modeling, as long as there is no break in the digital chain. Like laser cutting for example.

This can range from the wax jewelry model to machine a life-size formula 1

Why Rapid prototyping manufacturer?

Product design and development is a very complex process for rapid prototyping manufacturer in big brands in general. Moreover, it is crucial for big projects.

Also, the manufacture of prototypes during the development of a product is necessary in order to obtain parts. Similarly, it will allow the validation of the project.

Validation of the project on: its aesthetics, its geometry, its functionality or its technology.

Rapid prototyping manufacturer brings new possibilities by making it possible to produce parts without molds or dies.

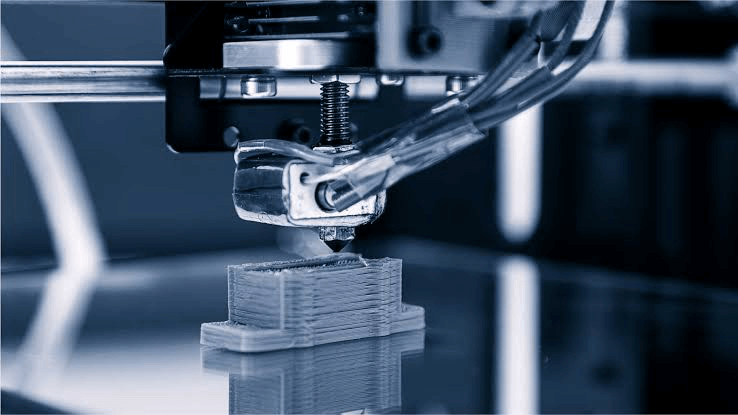

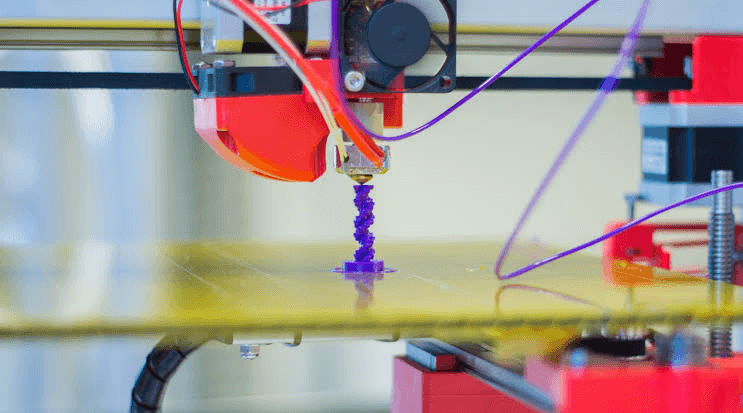

3D printing for rapid prototyping

3D printing is one of the techniques used to quickly produce prototypes. With this in mind, rapid prototyping manufacturer uses a 3D printer and modeling software.

The additive manufacturing process will allow the 3D printer to create the prototype layer by layer. It will respect all the details of the model, even the most sophisticated elements.

Different types of material can be used depending on the devices and the desired design. Such as:

- Metal 3D printing.

Regarding prototyping, the exploitable 3D technologies are DMLS, MJF, SLS, polyjet, SLA and FDM.

Rapid prototyping manufacturer CNC machining

CNC machining is part of the rapid prototyping manufacturing process. This technique is crucial for prototypes requiring high precision since its principle is favorable to unit production.

The main devices used are the milling machines. Rapid prototyping manufacturer control them by the adapted computer program and the 3D file of the prototype.

Unlike 3D printing, CNC machining uses the subtractive method. It consists of cutting the desired object from a block of material, such as metal and plastic.

Thermoforming

Thermoforming consists of melting material under heat and depositing it in the mold. The pouring of this material into the mold can be done by injection, depending on the system used.

The advantages of Rapid prototyping manufacturer

These techniques have revolutionized the way of creating prototypes. Whatever system is used, the advantages are:

- reducing the manufacturing cost

- the production of a prototype exactly identical to the preconceived model

- The speed of conception.

The rapid prototyping brings together a set of tools which, arranged between them. They make it possible to achieve intermediate representation projects for product design.

- digital models

- models

- prototypes and

- Pre-series.

These models will help to validate the different functions that the product must fulfill. For instance:

- functions of sign

- use

- exchange and

Three important aspects of Rapid prototyping manufacturer

Rapid prototyping manufacturer incorporates three essential concepts.

- Time

- cost and

- complexity of forms.

Time: the objective of rapid prototyping is to rapidly produce the models. It has the aim of reducing product development times.

Cost: rapid prototyping enables prototypes to be produced without the need for expensive tools. Moreover, it also guarantees the performance of the final product.

We are therefore able to explore different variants of the product being developed in order to select the most appropriate solution.

Complexity of forms: machines proceeding by adding material are capable of producing extremely complex forms. It cannot be achieved by processes.

In addition, the models produced will help to validate the product. Moreover, it will check whether it is in adequacy with the functionalities which have been attached to it.

Conclusion

Rapid prototyping brings together a set of tools that create the intermediate elements of product design: digital models, models and prototypes.

Thus, it will make it possible to go from the invention phase to that of production, and to design the various tools and methods of the latter.

Since the world in improving towards new technology, innovation solutions are crucial. Above all, Rapid prototyping manufacturer have become imperative for faster production.

If you are looking for a professional rapid prototyping, you need not to go anywhere. https://www.essaii.com/ is a hub of expert rapid prototype manufacturers.