Plastic Extrusion Manufacturer: An Introduction to Plastic Extrusion

2020-06-11Plastic Extrusion Manufacturer: A Basic Guide on Plastic Extrusion

Being a plastic extrusion manufacturer, we often come across questions like what is plastic extrusion? Is it useful? Are there any subcategories? We understand the concept might be alien for people outside the industry.

After all, it does involve some technicality. Thus, making it off-limits for people who do not have a taste for it. Nonetheless, having general knowledge is never bad. So, today, in our blog post we are going to focus on the basics of plastic extrusion.

By the end of the blog, you would be familiar with its basic idea, types as well as its advantages. So, without any further delay, we should get started!

Introduction to Plastic Extrusion

For starters, you need to know what plastic extrusion is. In the technical world, people define this concept as the transformation of solid plastic mass into usable products. The manufacturer would take the plastic mass and turn it into the desired shape.

It is possible to either use these shapes to create additional products, or you can use them as end-products. It all depends upon your requirement. We hope, you now get the basic idea regarding plastic extrusion.

Now, let's dig a little deeper.

There are three main plastic parts producing processes that incorporate plastic extrusion. These processes include blow molding, injection molding, and extrusion. Each process is important and different in its own way.

Extrusion

It is a continuous process. Something, which the other processes lack. In extrusion, you would continuously convert pellets, solid plastic mass, or powder into a melted form. You would also be pushing the melted form into a shape using a die.

The shape is the one that you want the plastic to attain eventually. However, it is not the final part. This shape does go through multiple other processes to achieve the respective results. Some of these operations include pipe, profile, cast film, blown, sheet, or pelletizing.

Below, we have listed the outputs from these processes.

You can turn plastic sheets into either food storage containers or drinking cups.

Plastic pipes that help in delivering water safely to your phone. You do not have to worry about lead contamination. In addition, these pipes do not clad the sides of your house, giving it a less pleasing overview.

For grocery bags, you would be using films. They not only increase the shelf life of the product but at the same time protect it from any sort of harmful contamination.

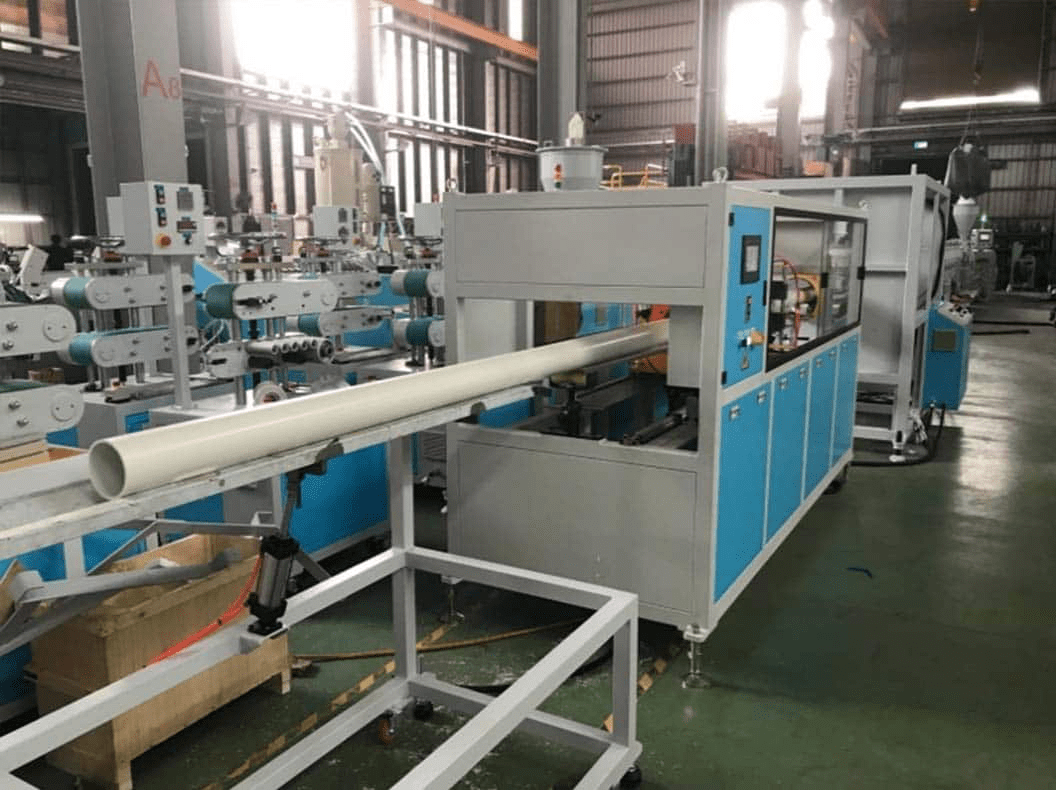

Every sub-process is different and one of a kind. It requires different downstream equipment, post extrusion, or dies in order to manufacturer the respective product. No matter, what type of process you use, all sub-processes do have one common component, the extruder.

The job of an Extruder

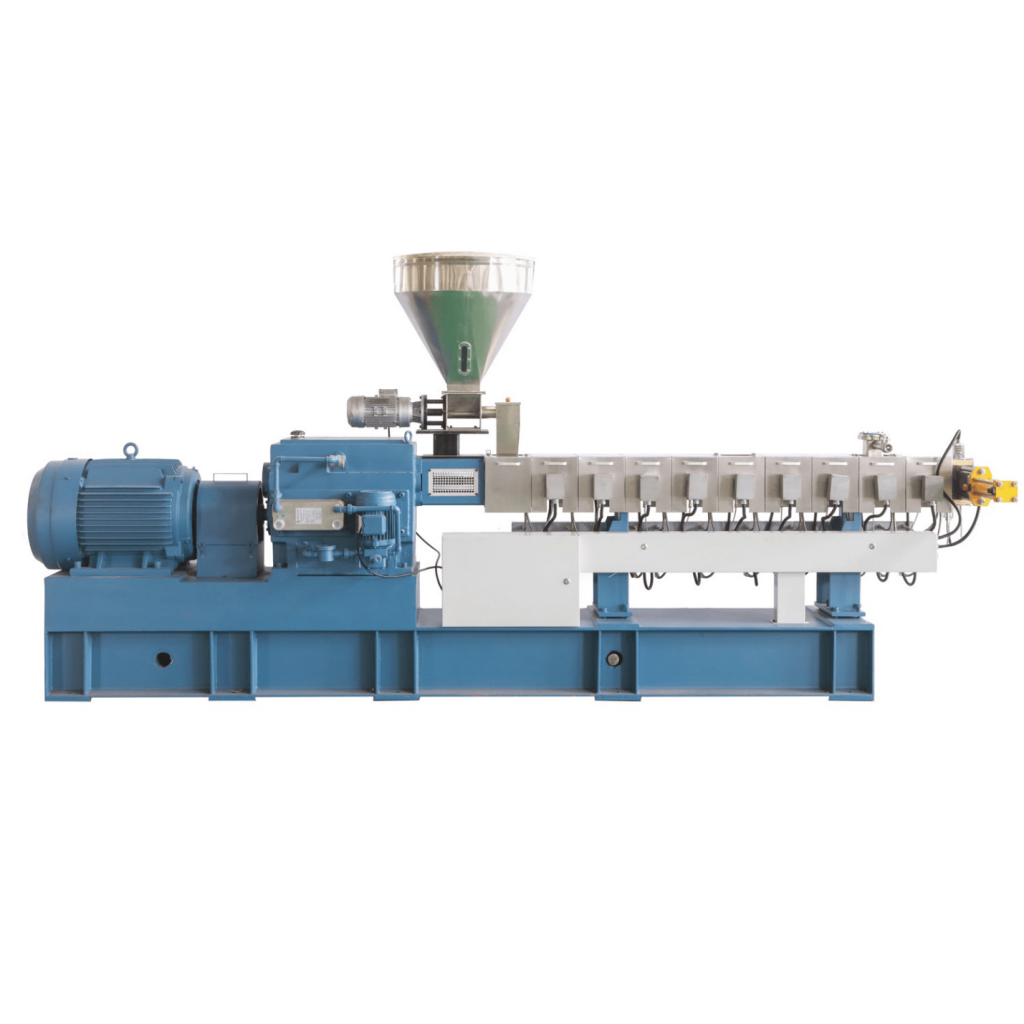

The main job of the extruder to turn the food stock or the solid plastic mass into a melted form. For this purpose, the plastic extrusion manufacturer tends to rely on two different extruding technologies. They can either go with the twin-screw technology or the single screw technology.

Single Screw Technology

Plastic extruding manufacturers around the globe prefer the single screw technology over the twin-screw one. It is most common in the industry. The great thing about this technology is that you can apply is to a wide range of polymer types.

In addition, the technology is applicable to almost all common extrusion processes.

Twin Screw Extruder Technology

On the other hand, we have the twin-screw extruder technology. This is a more sophisticated form of technology. The manufacturers further break down the technology into two parts, the co-rotating, and the counter-rotating technologies.

With the counter-rotating extruder incorporate 2 screws. These screws rotate in opposite direction to each other and they intermesh as well. The co-rotating twin screws also use 2 screws. However, these screws rotate in the same direction and they intermesh as well.

Regardless of the type of technology you use, single or twin, their main objective is the same. They want to turn a solid mass plastic into a melt. Both of these technologies use slightly different mechanisms to serve the same purpose.

Note: The beginning of the intrusion process is the transformation process. Therefore, you need to be extremely careful as it does have a great impact on the entire process.

To highlight its importance, manufacturers call extruder as the heat of the extrusion process. Likewise, they label the extruder screw as the heat of the extruder. After all, the lack of extruder screw performance would have an adverse impact on the entire extrusion process.

The screw needs to perform at the optimal level in order for the extrusion to become a great success.

Plastic Extrusion Manufacturer Categories Extrusion as below

Film/Sheet Extrusion

This particular extrusion process uses a flat die to extrude the molten plastic material. In order to find the sheet or the film’s thickness, the process uses cooling rolls. These rolls are also helpful for determining the texture of the material’s surface.

It is possible to attain the sheet thickness between 0.2 to 15 mm. However, the thickness does depend upon your product or component requirement. It is possible to make a thin flat film or sheet. For effective results, plastic extrusion manufacturer recommends using polystyrene plastic as raw material.

Blown Film Extrusion

This process also uses a die, however, instead of flat the die is like a vertical cylinder. It also comes with a circular profile. A pair of nip rollers would pull the molten plastic from the die in an upward direction. To inflate the tubes, you would be using compressed air.

Moreover, there is an air ring installed around the die. The reason for the air-ring is to cool down the film as it moves upwards. To force the compressed air into the center of a circular profile, you will notice an air inlet.

This air inlet helps in creating a bubble. It is possible to increase the cross-section around two to three times the die diameter. To collapse the bubbles, you would be needing the collapsing plate. Later, the lay-flat comes into action for flatting the bubbles into double layer films.

Over Jacketing Extrusion

Another name for over jacketing extrusion is the wire coating process. From the center of the die, you will be pulling a bare wire. For coating over the wire, you can either use the jacketing or pressure tooling.

These two processes are different; however, they serve the same purpose. Nonetheless, we do recommend jacketing tooling if you require adhesion or intimate contact between coating and wire. In case of pressure tooling, you would retract the wire into the die.

It would then come in contact with the molten plastic. Do remember, that there needs to be a high pressure while the wire is coming in contact with molten plastic. On the other hand, for jacketing tooling, the die comes first, and then the molten plastic would cover the wire after it tends to extend.

You would be feeding the bare wire using the die. It would not come in contact with the molten plastic until it is within the die. The major difference between these processes is that wire positioning with respect to the die.

Plastic Extrusion: Advantages

If there are two or more machines available to feed the single die, it is possible to have co-extrusion. This is highly effective if the product requires multiple layers of different materials.

With co-extrusion, you can add a top layer of high-end material to give the product an expensive look, while using low-cost material underneath to save the overall product cost.

It is a cheaper plastic manufacturing technique. It is possible to improve product durability, properties, fire resistance, static, etc. using different additives.

With plastic extrusion, it is possible to achieve complex shapes with different textures, thickness, colors, etc. You can have access to numerous different shapes and colors, all because of the state-of-the-art technology.

The process is highly effective for producing shapes continuously.