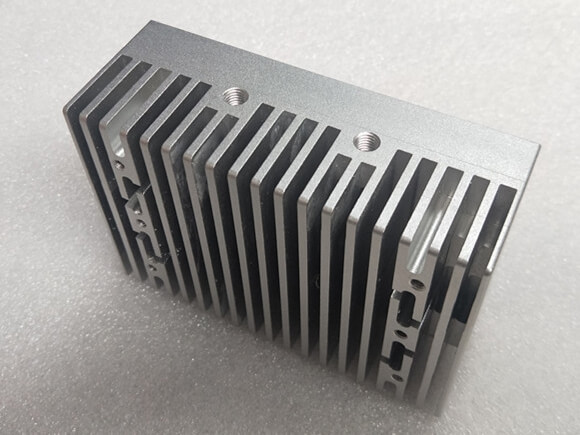

Rapid ရှေ့ပြေးပုံစံများအတွက်စိတ်ကြိုက် CNC လူမီနီယမ်စက်အစိတ်အပိုင်းများ

- Rapid Injection Molding

- ဒီဂျစ်တယ်အလင်းထုတ်ယူခြင်း

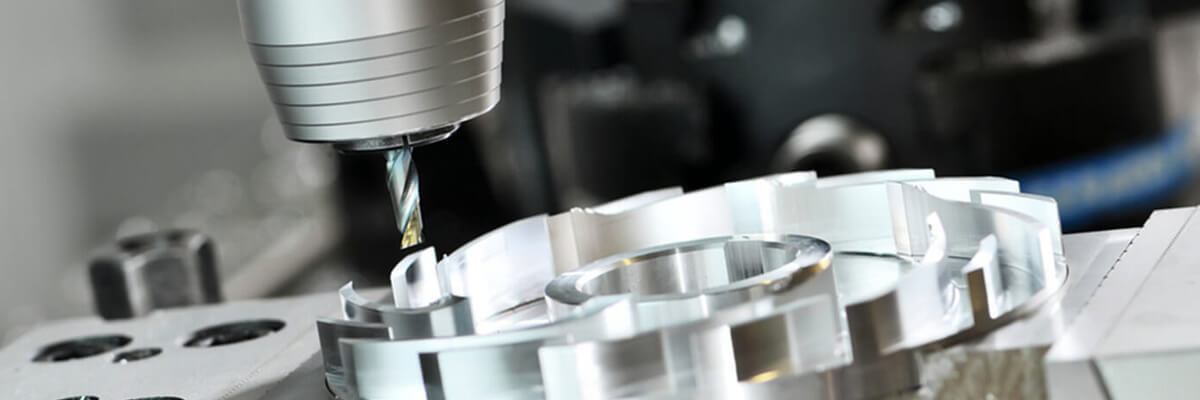

- CNC စက်

- Selective Laser Sintering (SLS)

- Laminated Object Manufacturing

When you need rapid prototype parts processed with high precision, please ask us for help. Essai offers you high quality rapid prototypes in a variety of industries.

Rapid Prototype is a quick, easy, cost effective way to turn great ideas into successful products. Do you need concept modeling to put your newest ideas to the test? What about functional prototyping to gauge performance before committing to costly production tooling? Rapid prototyping solutions from Essai will give you the flexibility to create, test and refine in ways you never thought possible so you can go to market faster than ever before.

Advantages of Rapid Prototype

လျင်မြန်သောရှေ့ပြေးပုံစံသည်အင်ဂျင်နီယာ၊

- သဘောတရားများကိုပိုမိုလျင်မြန်စွာစူးစမ်းလေ့လာနိုင်စွမ်း အချိန်နှင့်ကုန်ကျစရိတ်အတွက်ဤထိရောက်မှုကအသင်းများကိုထုတ်ကုန်တစ်ခု၏ဂုဏ်သတ္တိများနှင့်ဒီဇိုင်းကိုပိုမိုလွယ်ကူစွာနားလည်စေရန်ထုတ်ကုန်တစ်ခု၏အမြင်ကိုကျော်။ ကျော်လွန်သွားစေသည်။

- ထပ်ခါတလဲလဲဒီဇိုင်းများ Apply နှင့်ထုတ်ကုန်များ၏အကဲဖြတ်ခြင်းနှင့်စမ်းသပ်ဘို့ခွင့်ပြုအပြောင်းအလဲများကိုထည့်သွင်း။ ဒီကြားမှာဖြစ်စဉ်ကိုနောက်ဆုံးထုတ်ကုန်ဖွံ့ဖြိုးဆဲနှင့်သန့်စင်ရန်လမ်းပြမြေပုံပေးသည်။

- သဘောတရားများကိုအတိုချုပ်နှင့်ထိရောက်စွာဆက်သွယ်ပြောဆိုနိုင်ခြင်း။ လျင်မြန်သောရှေ့ပြေးပုံစံသည်စိတ်ကူးများ၊ ရုပ်ပုံများနှင့်အယူအဆများကိုပြားချပ်ချပ်နှင့် ၂ ဖက်မြင်ပုံရိပ်များမှဖောက်သည်များ၊ လုပ်ဖော်ကိုင်ဖက်များနှင့်ပူးပေါင်းသူများထံမှလက်တွေ့လုပ်ဆောင်နိုင်သည့်လက်ကိုင်ထုတ်ကုန်များဆီသို့ယူဆောင်သွားသည်။

- အယူအဆတစ်ခုကိုနှိုက်နှိုက်ချွတ်ချွတ်စမ်းသပ်ပြီးစွမ်းရည်။ ဒီဇိုင်းအားနည်းချက်များကိုသေးငယ်သောပမာဏဖြင့်လျင်မြန်စွာရှေ့ပြေးပုံစံဖြင့်မောင်းနှင်နိုင်ခြင်းသည်အစောပိုင်းအကဲဖြတ်မှုတွင်ထင်ရှားနိုင်ဖွယ်မရှိသောအကုန်အကျများသောဒီဇိုင်းအားနည်းချက်များကိုဖယ်ရှားပေးသည်။

- တပ်ဆင်ခြင်းနှင့်ကိရိယာတန်ဆာပလာများမလိုအပ်သောကြောင့်အချိန်နှင့်ငွေကုန်သက်သာသည်။ ကွဲပြားခြားနားသောဂုဏ်သတ္တိများနှင့်ပစ္စည်းများနှင့်အတူရှေ့ပြေးပုံစံထုတ်လုပ်ရန်တူညီသောပစ္စည်းကိရိယာများကိုသုံးနိုင်သောကြောင့်ကုန်ကျစရိတ်များနှင့်အချိန်ကုန်သက်သာမှုအနည်းဆုံးဖြစ်သည်။

Rapid Prototype Applications

Rapid prototyping is applicable to many materials and technologies, making it a versatile technique that can be employed for numerous applications. A few ideas include the following:

- Concept models provide designers with the opportunity to validate both their ideas and the assumptions that lie behind them. A physical concept model is an ideal way to explore a concept, demonstrate its validity to stakeholders and/or create communication surrounding it.

- အလုပ်လုပ်သောရှေ့ပြေးပုံစံများသည်ဒီဇိုင်းနာများနှင့်တီထွင်သူများအားအပြီးသတ်ထုတ်ကုန်၏တိကျမှန်ကန်သောကိုယ်စားပြုမှုကိုပေးသောအသေးစိတ်အချက်အလက်များကိုနောက်အဆင့်သို့မရွေ့မီယင်း၏တရားဝင်မှုကိုအတည်ပြုရန်ခွင့်ပြုသည်။ ကုန်ပစ္စည်း၏မသင့်လျော်မှု၊ ဒီဇိုင်း၊ ထုတ်လုပ်နိုင်မှုနှင့်လုပ်ဆောင်နိုင်မှုတို့ကို၎င်းကိုအပြည့်အဝထုတ်လုပ်မှုအသုံးစနစ်သို့မရွှေ့ပြောင်းမီစမ်းသပ်စစ်ဆေးနိုင်သည်။

- အလုပ်လုပ်သောရှေ့ပြေးပုံစံသည်ထုတ်လုပ်ရန်အတွက်စီးပွားရေးအရဖြစ်နိုင်ခြေရှိကြောင်းသက်သေပြခြင်းသည်လျင်မြန်သောရှေ့ပြေးပုံစံ၏နောက်တစ်ခုဖြစ်သည်။ လျင်မြန်သောရှေ့ပြေးပုံစံဖြင့်ဖြစ်နိုင်သမျှကုန်ကျစရိတ်နှင့်အကျိုးဖြစ်ထွန်းနေစဉ်အတွင်းစိတ်ကျေနပ်စရာကောင်းသောလုပ်ဆောင်နိုင်မှုနှင့်ဗေဒ၏ကျေနပ်ဖွယ်ကောင်းသောဟန်ချက်ကိုရရှိသောစိတ်ကူးရှေ့ပြေးပုံစံရှိသည်။

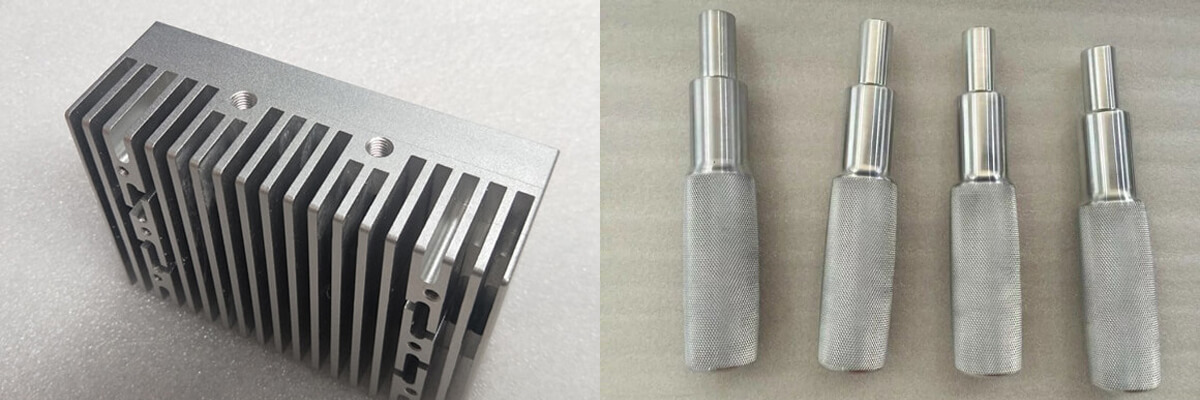

| CNC စက်သို့မဟုတ်မ | CNC စက် |

| Micro Machining သို့မဟုတ်မ | Micro Machining |

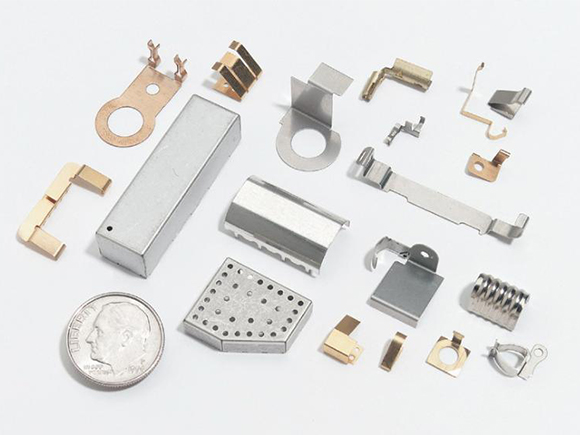

| ပစ္စည်းစွမ်းရည် | အလူမီနီယမ်, ကြေးဝါ, ကြေး, ကြေးနီ, ခိုင်မာသောသတ္တုများ, အဖိုးတန်သတ္တုများ, သံမဏိ, သံမဏိသတ္တုစပ် |

| ပစ္စည်း | Metal |

| ဝန်ဆောင်မှု | စိတ်ကြိုက် OEM |

| လျှောက်လွှာ | Industrial Equipment |

| Equipment | CNC Milling Machine |

| မျက်နှာပြင်ကုသမှု | Powder Coating |

| လက်မှတ် | ISO19001 |

| အထုပ် | ပလတ်စတစ်အိတ်များ & ပုံး ဖောက်သည်ရဲ့လိုအပ်ချက် |

Essai ပေါ် မူတည်၍ ကောင်းခြင်း

၁။ အလူမီနီယမ်ထုတ်ကုန်များကိုသွန်းလောင်းခြင်းကိုအပြိုင်အဆိုင်စျေးနှုန်းဖြင့်ရောင်းချသည်။

၂။ ကျွန်ုပ်တို့သည်ဆယ်စုနှစ် ၁၄ ခုကျော်သောသတ္တုစပ်အလွိုင်းအစိတ်အပိုင်းများကိုအထူးပြုသည်။

၃။ လူမီနီယံသတ္တုစပ်နှင့်အခြားထုတ်ကုန်များအတွက်အကောင်းဆုံးကျွမ်းကျင်သူများနှင့်ခေတ်မီနည်းစနစ်များကိုကျွန်ုပ်တို့အသုံးပြုသည်။

4. ကျွန်ုပ်တို့သည်ဟာ့ဒ်ဝဲ၊ ကွန်ပျူတာ၊ ကျန်းမာရေးစောင့်ရှောက်မှုနှင့်မော်တော်ယာဉ်စသည့်အမျိုးမျိုးသောစက်မှုလုပ်ငန်းများတွင် ၀ န်ဆောင်မှုများကိုပေးသည်။

၅။ ကျွန်ုပ်တို့၏ထုတ်ကုန်များကသင့်အားနာမည်ကောင်းရရန်အာမခံပြီးအရည်အသွေးမြင့်မားသောစံနှုန်းများကိုကျွန်ုပ်တို့လိုက်နာသည်။

၆။ ကုန်ပစ္စည်းများကိုစစ်ဆေးခြင်း။

၇။ ကျွန်ုပ်တို့၏အဖွဲ့အစည်းတွင်အဖြေတစ်ခုထက်ပိုပြီးဖြစ်နိုင်သည်။

၈။ သင်၏အကြံဥာဏ်များနှင့်ဒီဇိုင်းများကိုကျွန်ုပ်တို့၏ကျွမ်းကျင်သူများမှအဓိပ္ပါယ်ဖွင့်ဆိုချက်အသစ်ပေးလိမ့်မည်။

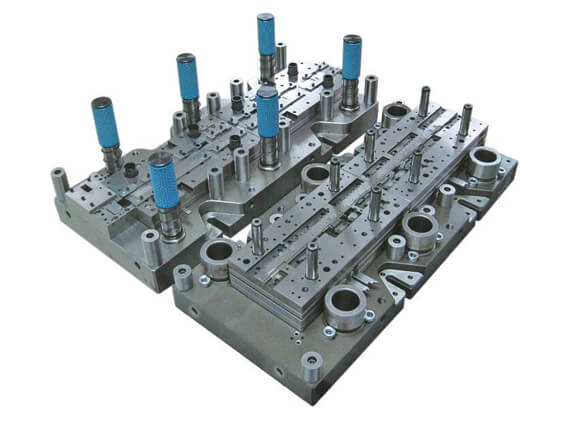

- Rapid Injection Molding – A low-cost rapid mold can be used for a small number of parts for a low cost.

- Digital Light Processing – It has good tolerance to the design and has a good surface finish.

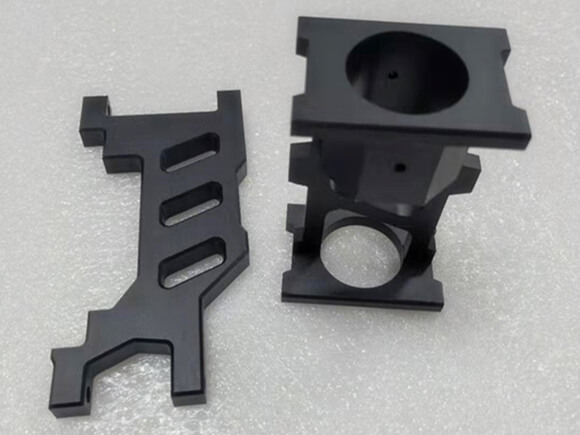

- CNC Machining – An ideal choice for plastic without costly tooling. It holds tighter tolerances and has a better surface.

- Selective Laser Sintering (SLS) – SLS is for plastic prototypes with intricate internal designs.

- Laminated Object Manufacturing – A good option using thin laminates laid layer by layer for plastic. The designs should not be complex, but LOM is a low cost compared to others.

- Selective Laser Melting (SLM) – SLM is the preferred option for parts requiring high strength, high durability, and complex intricate design.

- Fused Deposition Modeling (FDM) – FDM includes a low cost, ease of us, and using multiple plastic types and colors in one prototype.

- Stereolithography (SLA) – good for low volume production parts with a quality finish and increased strength.

- Binder Jetting – A big advantage in making multiple parts at one time at a lower cost.

တူညီသောအမှု

အမျိုးမျိုးသောစက်မှုလုပ်ငန်းများအတွက်စီးပွားရေးလုပ်ငန်းများအတွက်နည်းပညာပိုင်းဆိုင်ရာဟာ့ဒ်ဝဲပံ့ပိုးမှု။

မလုံလောက်ဘူးလား

ကျွန်ုပ်တို့ထံ ဆက်သွယ်၍ သင်၏လုပ်ငန်းကိုယခုပင်စတင်ပါ။

ရုံးခန်း : No.72-6၊ huanguan တောင်လမ်း၊ Longhua New District Shenzhen၊ 518110 တရုတ်

စက်ရုံ - အမှတ် ၃၃၃ Xiangmang အနောက်လမ်း Qingxi မြို့၊ Dongguang၊ တရုတ်