Dewaxing Casting: Knowledge Regarding De-waxing of the Shell

2020-08-24Importance of Dewaxing Casting

Dewaxing casting holds great importance in the investment casting process. You need to have proper knowledge as it can define the quality and composition of the mold. There are many aspects of the de-waxing casting technique.

In the course of this article, we going to talk about the dewaxing of the shell. So, without any further delay, let us get started!

Introduction to Dewaxing Casting

To ensure the quality of investment cast mould, it is imperative to pay close heed to the wax removing process. After all, it is among the most important step of the cost mould. Dewax can lead to a number of problems.

For instance, it can cause microcracks. After all, the de-waxed or the green shells are fragile and vulnerable before firing. To hold the components of the shells together, manufacturers either use fibers and polymers or colloidal networks.

In most cases, the manufacturers depend upon the autoclaving method for removing wax patterns. However, there are certain manufacturers that de-wax via the flash firing method. The choice greatly depends upon the manufacturer’s preferences and requirements.

The major benefit of using steams instead of the air in the baking oven is to ensure effective and efficient energy transfer to the interface layer of wax. Moreover, the autoclaving methods permit the reclamation of the melted wax.

It also reduces the release of contaminating gas especially when you compare it with the flash firing method. There is little to no amount of wax left behind after the completion of the autoclave dewaxing process. This then results in less production of ash during the firing procedure.

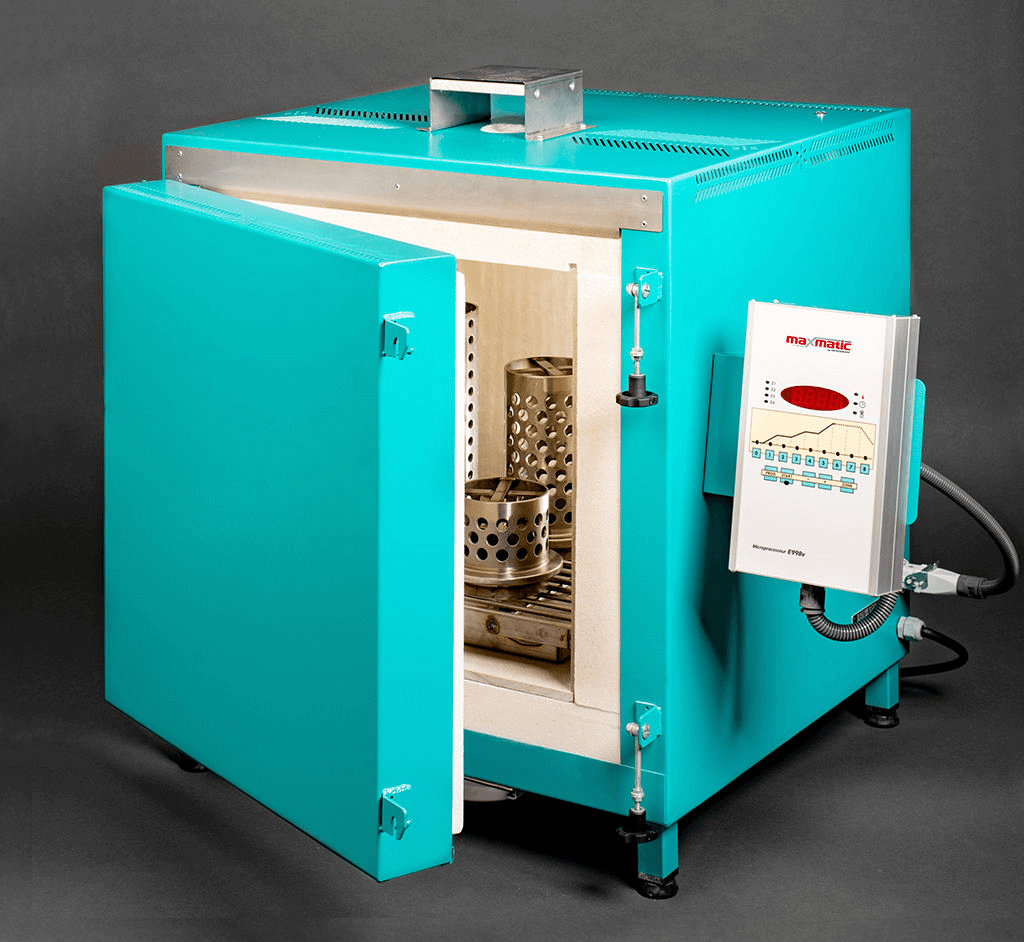

Autoclaving Method

For an instant heat source, the autoclaving procedure uses steam. The steam is familiarized with the shell surface. The constant introduction of the steam leads to a change of state in the solid wax present in the shell.

The wax starts to melt and at the same time, there is increased stress on the shell’s inside surface. The stress is the result of the liquid volume expansion and the phase transformation.

NOTE: It is vital to release the pressure build inside the shell due to expansion as soon as possible. Lack of pressure release would lead to the cracks in the shell.

Release Mechanism

The pressure release mechanism is simple and effective. What happens is that after the steam penetrating the shell melts the solid wax inside, the melted wax then passes into the prime coat. To enter the prime coat, the wax penetrates the shell.

The decrease in the shell stress is due to the penetration of the liquid wax into the prime coat. Likewise, the polymer present in the shell makes it robust and strong. It offers a better system for absorbing the pressure that is building up in the shell.

Prime Coat- Shell Properties

Manufacturers greatly emphasize the fact that relieving the right amount of pressure via the prime is important. However, it is important to understand that the pressure relieve should not compensate for the integrity of the prime coat nor should it have an adverse impact on the surface roughness.

To increase the shell's ability to withstand pressure, manufacturers something incorporate polymers into the prime slurry. The polymers also help absorb the wax expansion. Thus, making the shell sturdy and strong.

It is important to wet the prime coat using the liquid wax as this would ensure better shell permeability. There are several factors that influence surface wetting. For instance, the temperature, surface heterogeneity, roughness of the prime coat surface, wax liquid characteristics, and the rate of wetting.

Backup Coat- Shell Properties

In order to avoid all sorts of shell cracking, you need to pay extra attention to back up coats. After all, these coats need additional strength for the penetration of the shell cracking. The number of back up coats greatly depends upon the mechanical strength and the slurry system.

You can have as little as four backup coats or the number can go up to 12 or so. Do bear in mind that the shell thickness would lead to an increase in the heat capacity of the shell. Thicker the shell, higher its heat capacity.

Also, higher thickness requires additional steam energy to convert the solid wax within into liquid wax. Thus, you need to have a balance of the permeable shell system. Prevent the right amount of steam penetration along with good mechanical strength.

To further enhance the stability and the survivability rate, it is a good idea to add polymers to the shells.

Dewaxing Casting Properties

For the making of investment casting-pattern waxes, manufactures mainly use the microcrystalline waxes and the paraffin waxes as the base wax. They then add plasticizer, fillers, and resin. However, the decision of adding plasticizer, resin, and fillers depends upon the application type.

Each factor offers different benefits. Like, adding fillers to the wax would reduce shrinkage, it would enhance dimensional performance and result in better mechanical properties.

For the designing of wax good for autoclaving dewaxing casting, there are different parameters that hold importance. For instance, you would have to focus on the conductivity, heat capacity, melting point, viscosity, and thermal expansion.

Autoclave Dewaxing Suggestions

In most cases, the manufacturers suggest running auto-clave at least six bars in three seconds. Then allow the pressure to recover up to eight or nine bars. Do bear in mind that there should be a steady increase in the steam pressure along with the simple pressure.

Higher depressurization rate would have an adverse impact on the mold’s pressure pockets as well as the case of the condensed steam. This would then be leading to the cracking of the mold.

Also, to ensure the effectiveness and efficiency of the mold, we do recommend that you run a couple of dummy cycles. This would provide you with the idea of the outcome. It is important to incorporate seal inspection, regular maintenance, safety systems, and door operation in your daily inspection routine. However, this setting does differ from manufacturer to manufacturer.

In case you are looking for more information on dewaxing casting, reach out to us today. We will provide you with all the information that you require.