Metal stamping suppliers: Method of high precision cold metal stamping

2021-07-09

The invention of the sheet was a real breakthrough in metalworking by metal stamping suppliers. And almost immediately, evaluating the plastic properties of the resulting product, the craftsmen thought about the fact that it can be given various forms.

The first example of cold stamping of metal was the simplest embossing.

The technology was complex and time-consuming. But before the invention of mechanisms that facilitate work, hundreds of years had to pass ...

Features of cold-forming metal parts provided by metal stamping suppliers

Here are some features of sheet metal parts

The “first swallow” of serial stamping technology flew to metalworking shops in the middle of the 19th century. It was then that the first machine tool equipment appeared and put into operation.

But stamping reached its truly outstanding scope with the advent of the automobile industry, and in the 30s of the last century - aircraft and rocketry. The manufacture and metal stamping suppliers of parts by cold stamping began.

How the metal stamping technology developed?

The technology has developed rapidly and, probably, even now, not everything has reached its peak. Modern stamping without heating to high temperatures is able to create parts of any shape and size.

Cold stamping of metal: technology

In the process of stamping, the preparatory stage - the manufacture of tooling - plays the most important role.

They evaluate what finishing shape the product should reach, how many stamping operations, and in what sequence it should go through. The result of the cooperation of these specialists is the creation of a “matrix-punch” pair that metal stamping suppliers supply to the industries.

After entering the workshop

Further, the project enters the workshop, where cold stamping of the metal takes place: under the influence of pressure, the matrix and punch stamp from sheets or strips of the required number of parts.

Cold stamping is called such with a degree of the convention:

After obtaining impressions of the desired shape, in order to strengthen them, final heat treatment is easy to carry - recrystallization annealing.

The design stage before the metal stamping suppliers supplies it to the end-users.

Volumetric cold stamping of metal

After contact with the die and the punch, the sheet metal turns into a three-dimensional product.

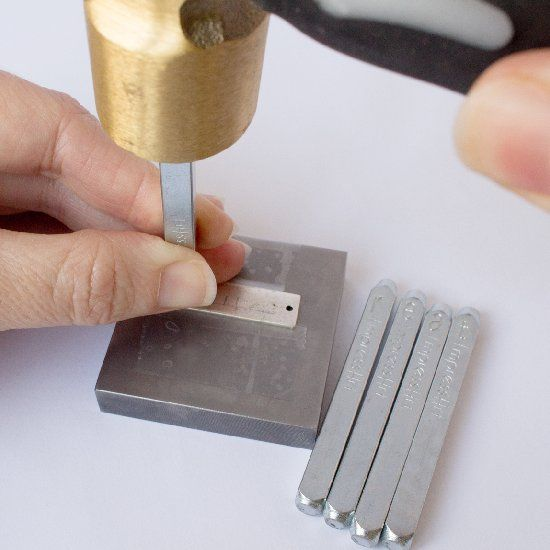

Before making shaping operations on the metal - drawing, upsetting, bending, forming, branding, and others.

Cold stamping of parts

The demand for cold stamping services in the capital has remained rather unstable for the past 30 years. The unexpected drops in the number of orders.

Customers get them reliable metal stamping suppliers because they are attracted by:

- high dimensional accuracy of products;

- elimination of surface defects;

- in comparison with “hot” technology - no traces of heat treatment: such as scale.

Working on the technology of cold stamping of metal is also beneficial for performers since it is less labor-intensive and more productive. Finally, both customers and contractors note the fact that this method of production consumes less material.

Types and methods of modern metal processing

Cold stamping, along with hot stamping, is one of the oldest technologies for processing sheet blanks.

For materials of high ductility, hard rubber stamping is common that metal stamping suppliers provide to the consumers. Its disadvantage is that in this way it is impossible to process a large series of rentals. Also interesting is the technique in which the metal changes its shape due to the pressure of the liquid.

In this process, the liquid substance acts as a punch, pressing the sheet tightly against the die. This technology is common when it is necessary to obtain products of complex shapes.

Blast-wave stamping

Blast-wave stamping is considered to be quite “aggressive”, but effective. As a result of the mini-explosion, the material comes into the matrix.

The choice of method determines by the complexity of the final part, as well as its dimensions.

Cold stamping

Metal stamping suppliers explain that cold stamping is a guarantee of high-precision parts

Despite the seeming archaism, the production of parts by cold stamping comes in demand.

Customers are attracted by:

- perfect accuracy of the obtained impressions,

- high process automation,

- low production process costs,

- small waste,

In fact, the most difficult stage of work is not the manufacture of a part, which is easy to produce quickly and, in any quantity, but the design.

Materials common in cold stamping explained by metal stamping suppliers

metal stamping operations are possible on all metals and alloys with sufficient ductility. But parts from them may be of limited scope.

Plain carbon steels are suitable for the production of manufactured goods and products that do not need to withstand heavy loads. Alloyed structural ones tolerate well not only stamping but also operations combined with welding.

Stamped billets made of aluminum are in demand according to the metal stamping suppliers, in the assembly of equipment and in instrument making, copper - in electronics, nickel-plated - in the production of tableware and jewelry.

Cold and hot sheet metal stamping

Hot stamping also accounts for a significant share of the metalworking market. Unlike cold metal stamping:

- there is less risk of damage to the workpiece;

- not so much effort is required for deformation, and hence the power of the equipment;

- the processed material can acquire a granular structure, and with it increased strength.

Drawbacks of Cold and hot sheet metal stamping

But this technique also has disadvantages and significant ones:

- much higher production costs;

- less accuracy, including due to temperature fluctuations;

- scale formed on the metal surface.

- deterioration of some of the mechanical characteristics of the material.

Types of equipment for sheet stamping get from metal stamping suppliers

The mechanical process of manufacturing parts by stamping is quite simple, but we can produce it on machines of different types and classes. As well as, customers can easily get them from metal stamping suppliers.

Consider the types of pressing equipment for stamping operations.

Crank presses are named after the type of drive. They are the simplest in the line of machines for this purpose. With their help, you can process sheets with a small cross-section and produce parts of very modest sizes.