How does machining cnc autoparts reduce cost and save time?

2020-07-03Best tips for cnc machining and manufacturing

Machining cnc autoparts has become indispensable in mechanical engineering, the automotive industry and shipbuilding. Technology has contributed greatly to industrial development in the past decades. Even 3D printing services have so far been unable to replace the original process.

What is the biggest advantage of machining cnc autoparts?

A huge advantage of CNC machines is their ability to reprogram. This does not take much time and allows the production of spare parts for individual orders.

Spare parts having a multistage or curved surface are more appropriate to produce on CNC lathes. Such technologies allow the production of a large number of high-quality spare parts in a short time.

Recently, there has been a tendency to introduce an end-to-end production process that will fully automate all stages of manufacturing parts. With the use of machining cnc autoparts, metalworking is accelerated at least twice.

What is machining cnc autoparts milling process?

Cnc milling is a milling process performed by controlling the machining conditions with a computer. NC means numerical control, and there were times when punch cards were used.

Nowadays, CNC, which performs NC is the mainstream, in machining cnc autoparts milling. Since it can be done automatically, it saves labor. And by controlling it with a machining program that uses 3D CAD/CAM software, it is also used for machining more complex shapes.

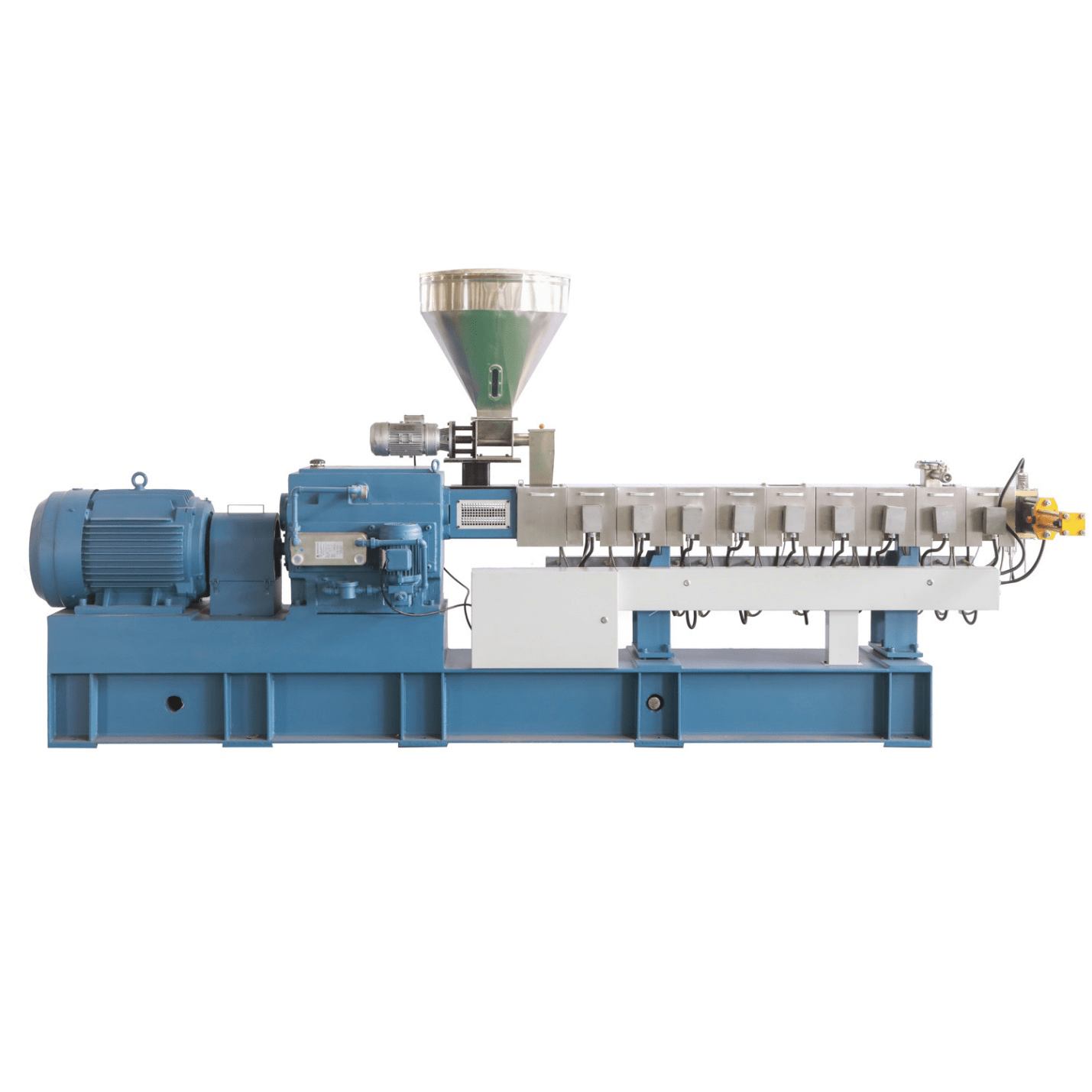

What is Machining center?

A machining center is a machine tool equipped with NC control. Moreover, it is not only a milling machine, but a multi-axis machine with multiple spindles with separate tools attached.

By using a machining center, you can combine linear movements and rotary movements one after another. And perform different types of cutting. Such as:

- drilling

- Curved surface machining continuously to machine more complicated shapes.

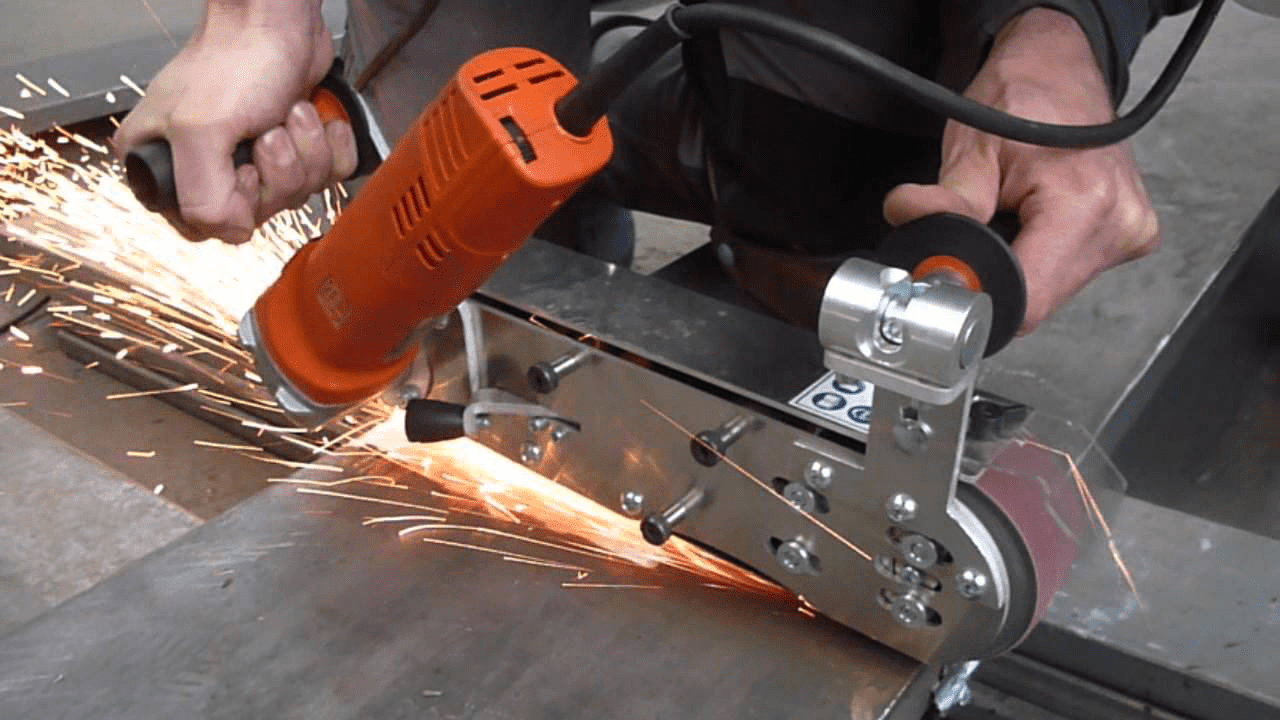

Production of machining cnc autoparts metal parts

In the manufacture of spare parts using milling processing, machining cnc autoparts will help to obtain high-quality parts. Similarly, it significantly reduces their cost.

The manufacture of metal parts on innovative equipment allows you to get geometrically perfect parts. Milling on CNC machines can even replace grinding products.

Work with metal using milling processing becomes an indispensable element in many areas of human activity. So, metalworking using CNC machines allows you to fulfill orders for the advertising industry. In particular the production of outdoor advertising.

Thus, the manufacture of spare parts, engraving on various surfaces is performed with a high level of accuracy.

In the case of the manufacture of spare parts from metal, the batch volumes do not matter. Machining cnc autoparts can easily cope with any number of parts.

Why machining cnc autoparts is also important?

Milling or turning metal on CNC machines allows minimizing the percentage of defective parts. A positive point is that the equipment is able to work day and night without fatigue and sick leave.

Production of spare parts according to the drawings

As mentioned above, CNC machines can produce spare parts even by individual order, regardless of the amount of work.

In order to order the production of spare parts according to the drawings, it is necessary to provide the company with a drawing of the necessary parts.

A drawing in any production is the main document for receiving an order. The drawing should contain all the details of:

- the order –

- the material

- its physical characteristics and

- various specific nuances.

It is necessary to manufacture an exclusive spare part, before manufacturing the entire batch. The part is tested to fulfill all the requirements stated in the order. In case of inaccuracies, the drawings are adjusted, and the production is perfected.

The choice, method of its production depends on the type, size and configuration of the part. The manufacture of machining cnc autoparts requires compliance with all stages of production.

Machining cnc autoparts planning

So, the next step is to draw up a plan, according to which the metalworking of the part will be performed.

It should be in mind that it is more profitable to produce large batches of spare parts. In the production of machining cnc autoparts on CNC machines, you can count on the identity of all parts of any batch to each other.

Metal products are found in almost any device or mechanism. Because of this there is a great need to complete the production of metal parts.

At the moment, the production process is almost completely automated. Moreover, it significantly improves the quality of parts. Similarly, it allows you to carry out work in a short time.

How does machining cnc autoparts reduce cost and save time?

It is possible to produce metal parts depending on the scope of the product and its characteristics on milling. Thanks to the introduction of machine tools with programmed control, large-scale production of parts is possible.

The latest turning and milling machines allow you to produce parts almost round the clock. The use of machining cnc autoparts makes it possible to practically eliminate the human factor from the manufacturing process of products. There are also very less chances of defective parts.

The production of metal parts is carried out using metal-cutting tools of a wide range of applications. Moreover, it allows manufacturer to manufacture products taking into account certain parameters.

The latest equipment allows you to fulfill both small orders and produce large batches of parts. Large-scale production of metal parts in the economic plan is more progressive.

Large batches of machining cnc autoparts products are produced regularly, at regular intervals. It allows us to constantly improve the production process. With the enlargement of the production series, the cost of the part decreases.

Modern programmed machine tools allow the production of:

- aluminum parts

- steel parts and

- various alloys to be established.

It is possible to carry out any work related to metalworking. Automation of the production process allows the production of parts with complex external and internal surfaces

With the use of innovative equipment, it became possible to manufacture machining cnc autoparts. Thanks to this, you can get a part that has long been discontinued or a product that has no analogues.

All products undergo rigorous testing for compliance with the terms of reference and quality level. The equipment is serviced only by highly qualified personnel, which significantly affects the quality of order execution.

Production of metal parts: materials

The production of machining cnc autoparts implies the manufacture of almost all categories:

- components

- mechanisms

It is possible to apply any type of thread or carry out gear cutting operations. Also, using laser technology, it became possible to perform high-precision parts and engraving on their surface. In addition, laser cutting allows virtually eliminating the consumption of metal.

In the manufacture of parts, a large role is assigned to the technical task. The more fully and competently it is compiled, the higher the quality and performance of the product.

To do this, you need to think through all the nuances. The production of parts according to the drawings carried out on machines.

It is possible to carry out grinding and coordinate boring operations with sheet metal of various thicknesses.

The production of metal parts carrier out on CNC machines to improve the accuracy and speed of manufacture. By saving time spent on production and material, the cost of the part is reduced.

The latest equipment allows the possibility of machining cnc autoparts reprogramming. in connection with which it is possible to produce a wide range of products. Also, CNC equipment allows you to achieve geometrically ideal product shapes.

The role of the design of machining cnc autoparts

Due to changes in safety regulations, the design plays a less important role today than it did ten years ago. Nevertheless, you should pay attention to the purchase of machining cnc autoparts.

Since it is an important feature and some manufacturers want to give the impression of higher quality, especially for cheap machines.