Investment Casting: A Comprehensive Introduction

2020-08-24A Brief Introduction to Investment Casting

Over the years, the investment casting process has evolved to a great extent. A modern dewaxing casting manufacturer can create extremely complex and complicated parts with disrupting the shell or the mold. Since the process is vital, therefore, you need to have its basic understanding.

In the course of this article, we are going to present to you a brief introduction to the investment casting process. We will explain its manufacturing along with applications. So, without any further delay, let us get started!

Process of Investment Casting

With investment casting, manufacturers are able to achieve highly detailed, complex, and accurate metal castings. The basic idea of investment casting comes from the ancient concept of the lost wax method. Since it offers a number of benefits, therefore, it is an important technique to create a number of equipment and parts.

History

There is no denying the importance of the investment casting process. You will be surprised to know that the lost wax process has been around since 4000 BC. The origin of the concepts is believed to be in the Middle East, North Africa, and Asia.

Initially, the concept was used to design and develop beautiful, complex sculptures and jewelry. In old times, the manufacturers relied on the bee’s wax. However, today, they are able to use any material that has a similar composition as that of the wax.

Heating and softening of the wax led to the creation of the desired shape. This basic concept has remained the same through the modernization and evolving process of the investment casting technique. The dewaxing casting manufacturer today use industrial molding compounds.

Modern Times

In the early 20th century, the wax casting process was popular for creating equipment for the dental industry. However, due to WWII, there was an increase in demand for almost ready parts. Numerous industries including the military were searching for ready parts in mass volume.

Thus, the casting process becomes popular and effective. Currently, manufacturers demand highly sophisticated parts and components. To achieve the required level of sophistication, they would have to rely on investment casting. The lost-wax method influences almost everyone’s life in one way or the other.

Investment Casting Process

Step One

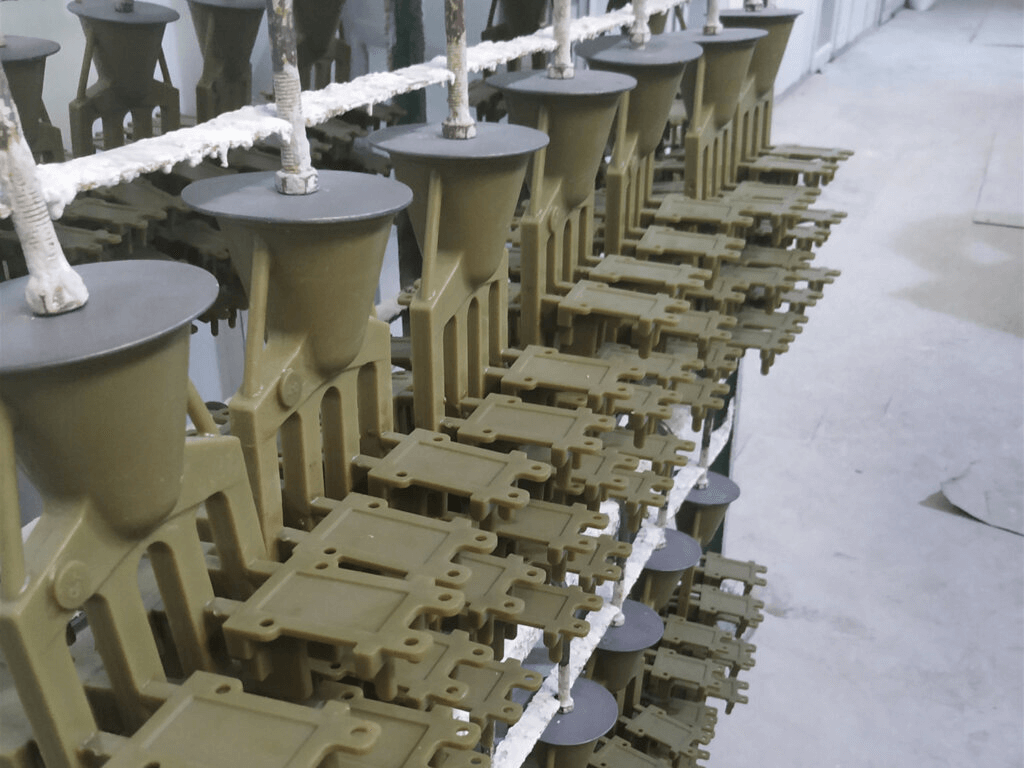

The first step involves the injection and assembling of the wax patterns. The manufacturer would inject the pattern onto a wax tree, or the gating system and the runner. In order to ensure smooth casting and dewaxing, the system incorporates a ceramic pour cup.

The cup is extremely useful in assisting both, dewax & casting processes. Usually, the soluble wax cores are present in the complex patterns. However, it is important to remove these cores before you start with the shelling and the assembling process.

In case, you require air or cavity passage in the final product, then you should use the core. It would yield the desired results.

Step Two

After you have assembled the wax patterns onto the runner and the gating system or the tree, you need to look for the minor imperfections. To do so, you check and dress the assembly of the gating system.

Remember, you need to pay extra attention to this particular step. After all, the flaw that goes unnoticed in this step is going to be part of the finished metal components. Something that you need to avoid as a manufacturer.

To provide the optimum wax substrate, most manufacturers recommend that you dip the assembly into the triol pattern etching and wash agent. Complete this step before heading onto the shelling process.

Step Three

Now it is time to apply a series of ceramic coating around the wax assembly. Doing this would result in the formation of the shell around the wax assembly. You would have to slowly increase the particle size. To be more specific, manufacturers first dip the wax assembly into a liquid slurry solution.

After that, they apply refractory stucco materials to it. Both of these things combine to make the required shell coating. Give some time to the shell material to set and then head towards the dewaxing process.

Step Four

It is time to remove the wax from the shell system. In most cases, the manufacturer relies on the steam in the autoclave dewax process. Some of them even use high temperatures, especially for the dewax flashfire method.

Regardless of the type of process you use, the left-out wax is collected and recycled. Now it is time to condition the shell and high temperature and fire it. This would lead to the manufacturing of precision casting moulds.

These moulds are ready for part creation. They now have the strength and the sturdiness to accommodate molten metal.

Step Five

To get rid of impurities as well as to enhance molten metal flow manufacturers add ceramic foam filters. These filters also add precision to the mould casting process. Next comes the cooling rates. In order to control these rates, there is a covering of fiber insulating blankets around the mould.

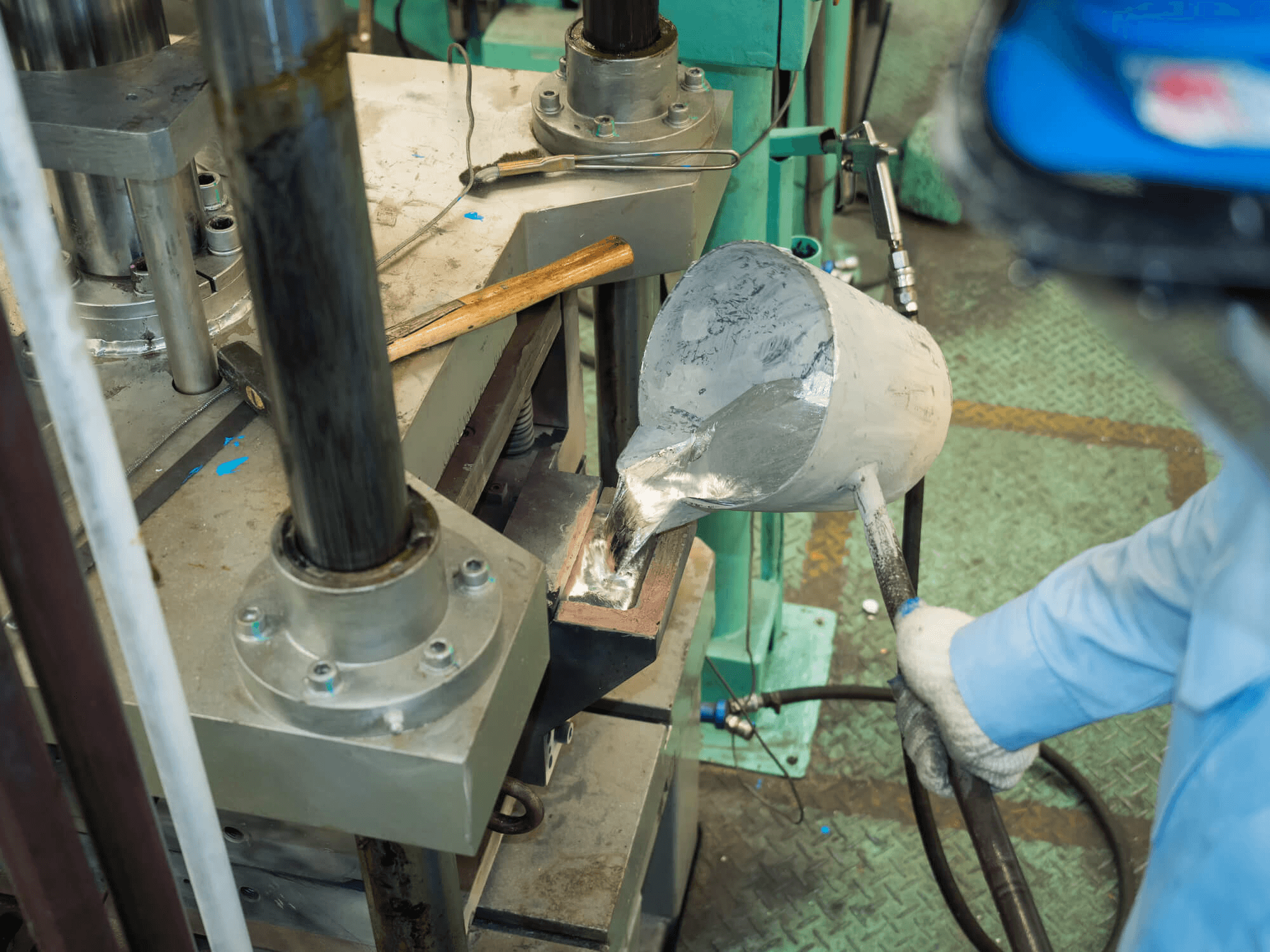

Once the moulds have the insulating covering, they will be introduced to the molten metal. Several techniques are available for the introduction process. For instance, the conventional hand pouring method or crystal-casting technology.

The type of technique used greatly depends upon the complexity of the part or the component. For instance, for highly complex alloys, we recommend using the single crystal-casting technique. However, in the case of lesser complicated parts, you can go with the orthodox hand-pouring method.

Step Six

Give ample time for the alloys and metal parts to cool down. After the cooling down process, you would need to remove the shell material via mechanical processes. In case, there are some internal ceramic cores left, you can remove them casting through a dissolving method.

You would have to dissolve the casting into a caustic solution and yield the desired results.

Step Seven

Lastly, it is time to remove the casting from the tree. The manufacturers would thoroughly inspect the finished product. They would even recycle the reaming material present in the gating system and the runner.

Do bear in mind that to yield effective results, the process requires complete attention and precision. You would have to control the process at every stage to ensure an accurate and error-free product. Only then will the product have the required mechanical characteristics and dimensions.