7 Basic Questions to ask from Die Fabrication Company in 2020

2020-07-22What is Die fabrication?

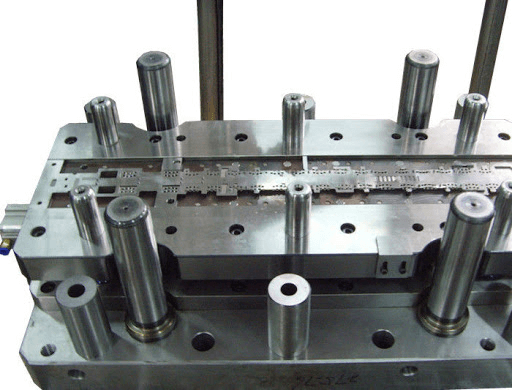

Die fabrication is basically a procedure of manufacturing to produce the parts of metal by compelling the melted metal below higher pressure within a die cavity. If talk generally we find that engineers fabricate these molds or die cavities with the help of hardened tool steel.

This procedure permits the products to be produce with the ability of high repetition. And also permits the all products with great precision and accuracy. The procedure of die fabrication also has the capability to manufacture nice details. In particular the organized surfaces which do not need more processing.

Die fabrication process has the quality to produce the parts that have following qualities:

- high detailed

- High accuracy.

We will be amazed to see that we have die fabrication products all around us. All the things you use in your daily life like from:

- you open the tap

- the handle of door

- even you drive the car

Almost everything you use in your daily life is made with the help of this process.

Which type of metals engineers use in Die fabrication?

In Die fabrication, engineers manufacture products with the help of metals, for instance:

- copper

- zinc

- magnesium

Furthermore, with the passage of time several types of alloys have created for the purpose to fulfill different requirements and needs of different applications.

How many kinds of Die fabrication are there?

There are numerous kinds of die casting or fabrication. And all of these types make use of a rare and extraordinary access in order to manipulate the shape and size of the store materials. For instance, cutting involves in order making full cuts which pervade all the way using the store material.

On the other hand, piercing includes the fabrication of several superficial and minor pits in the store material. Many other kinds of Die fabrication are:

- straight shearing

- scoring

- Creasing, etc.

Which kind of Equipment engineers use in Die fabrication?

Well, to decide the type of equipment in order to produce the target products, engineers totally depend on the certain types. Because for different kinds of materials engineers need different kinds of equipment for die cutting.

This procedure of die cutting basically needs a die cutting machine along with a cutting tool and a tool of punch also with a die. These machines generally powered by the following:

- electricity

Furthermore, all procedures of die fabrication need basically two things such as:

- die

- die cutting machine.

How many kinds of Die fabrication processes are?

Engineers further divide the process of die casting into two distinct categories, like:

- Cold Chamber Die casting

- Hot Chamber Die casting

Unluckily, this process of Die fabrication is entirely reasonable for alloys which will not attack the cylinder of the injection. And these reasonable alloys are like:

- magnesium

- zinc

Cold Chamber Die Casting:

Cold chamber die casting is basically the procedure to making use of a ladle in order to transport the melted metal from the holding kiln within the cylinder of injection or cold shot chamber. But it has a disadvantage also. And this is, this procedure is comparatively much slower in comparison to the hot chamber Die fabrication process.

Hence, engineers mostly use this procedure in order to produce aluminum parts. Because melted aluminum alloys have the inclination for the purpose to attack. And it also has undermined the cylinders of metal but it shortens the life of tool.

What are the benefits of Die fabrication parts?

The great ability of this manufacturing procedure is that, it does not restrict the shape of products.

And by using this process the products will be in their net shape. Moreover, Die fabrication has the following advantages like:

- Mass production at high speed:

- Durability

- Die and Mold Machining.

What is the history of Die fabrication?

The history of die casting basically starts from the mid of 1800. But until 20 years, this procedure had used for two main consumer purposes, like:

- cash registers

In the start, there were actually two basic metals which engineers had used in Die fabrications process. These were:

- lead

Afterwards these metals had replaced by two alloys in 1920, such as:

- aluminum

- zinc

Furthermore, as technology makes progress and becomes advance by the passage of time, this procedure also turns more effective and efficient. Because advanced technologies permit the more and more pressure within the process of injection.

Hence, this advancement also allows us to develop the parts which are actually closer to net shape. And they have also the ability of greater honesty and integrity like never before.

What are the advantages of Die fabrication?

The Die fabrication actually helps a vast variety of materials. It has the ability to perform on various metals. Furthermore, it also has the capability to perform materials such as:

- wood

Moreover, in order to support a vast variety of materials, this process also provides the profit of no or minor swarf. As you already have knowledge that maximum fabrication procedures which are related to manufacturing often generate waste material.

Hence, these chips that are basically known as waste materials. And basically, the production of this waste can make great bucks for most manufacturing companies.

However, with the help of Die fabrications, the manufacturing companies may have the ability to minimize the amount of chips that are produced within their relevant operations.

This process actually assists narrow forbearances. And also has the ability to make it perfect for producing applications which need uttermost precision. The normal forbearances actually start from minus 0.1 inches to plus 0.1 inches.

But with these forbearances it has possibilities to attain tolerances from minus 0.005 inches to plus 0.005 inches.

Where Die fabrications is is standing today?

Nowadays, Die fabrication has considered a highly qualified task because of the needs and requirements of the techniques

It has actually ability to cover the whole procedure. In which CAD designing also has included. Furthermore, it also consists of the selection of following:

- performing minute machining

- Materials and machining methods.

And all these cannot be made without die fabrication because they cannot be performed with automated procedures.