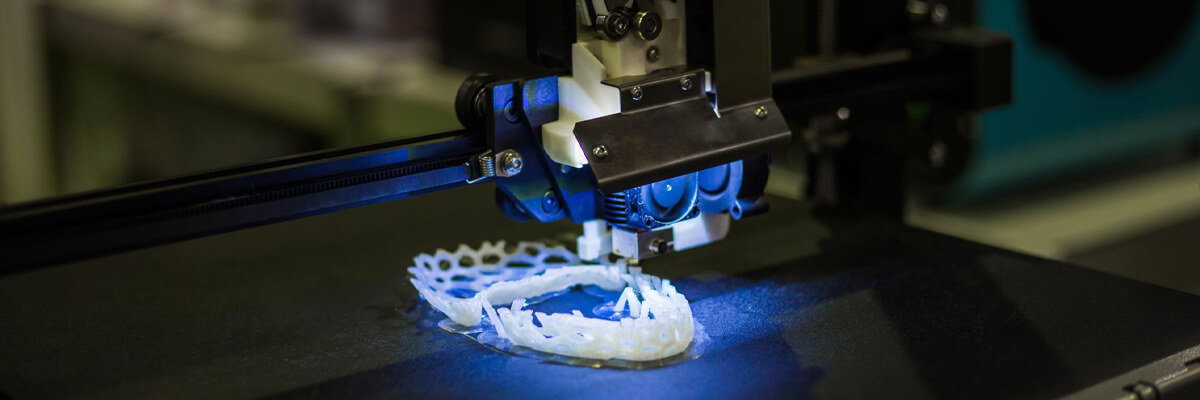

Cina Pemasok Kemasan Pengembangan Prototipe Cepat 3D

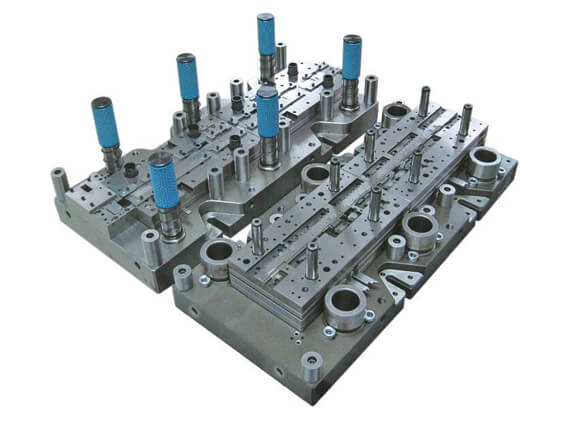

- Cetakan Injeksi Cepat

- Pengolahan Cahaya Digital

- Mesin CNC

- Selective Laser Sintering (SLS)

- Manufaktur Objek Laminasi

When you need rapid prototype parts processed with high precision, please ask us for help. Essai offers you high quality 3D rapid prototype in a variety of industries.

3D rapid prototype is a quick, easy, cost effective way to turn great ideas into successful products. Do you need concept modeling to put your newest ideas to the test? What about functional prototyping to gauge performance before committing to costly production tooling? Rapid prototyping solutions from Essai will give you the flexibility to create, test and refine in ways you never thought possible so you can go to market faster than ever before.

Advantages of 3D Rapid Prototype

Rapid prototyping provides engineer, design and development teams with a distinct advantage such as:

- The ability to explore and realize concepts more quickly. This efficiency in time and cost allows teams to move beyond the mere visualization of a product, making it easier to grasp the properties and design of a product.

- Apply repeated designs and incorporate changes that allow for the evaluation and testing of the product. This iterative process provides a roadmap to developing and refining the final product.

- Being able to communicate concepts concisely and effectively. Rapid prototyping takes ideas, images, and concepts from flat and 2 dimensional visuals to hands-on products that clients, colleagues, and collaborators can then see in action.

- The ability to thoroughly test and refine a concept. Being able to minimize design flaws with a small volume rapid prototype run helps eliminate costly design flaws that might not be evident during an early assessment.

- Save time and money since setup and tooling aren’t necessary. Because the same equipment can be used to produce prototypes with different properties and materials, the costs and time outlay are kept to a minimum.

3D Rapid Prototype Applications

Rapid prototyping is applicable to many materials and technologies, making it a versatile technique that can be employed for numerous applications. A few ideas include the following:

- Concept models provide designers with the opportunity to validate both their ideas and the assumptions that lie behind them. A physical concept model is an ideal way to explore a concept, demonstrate its validity to stakeholders and/or create communication surrounding it.

- Functional prototypes enable designers and developers to grasp the details that provide an accurate representation of the finished product by allowing them to verify its validity before it moves onto the next stage. The fit, design, manufacturability, and function of the product can be tested prior to moving it into full production mode — an infinitely more costly process.

- Proving that a working prototype is also going to be economically feasible to manufacture is another application of rapid prototyping. Having a fantastic prototype that achieves a satisfactory balance of functionality and aesthetics while also being cost-effective is possible with rapid prototyping.

| Mesin CNC atau Tidak | Mesin CNC |

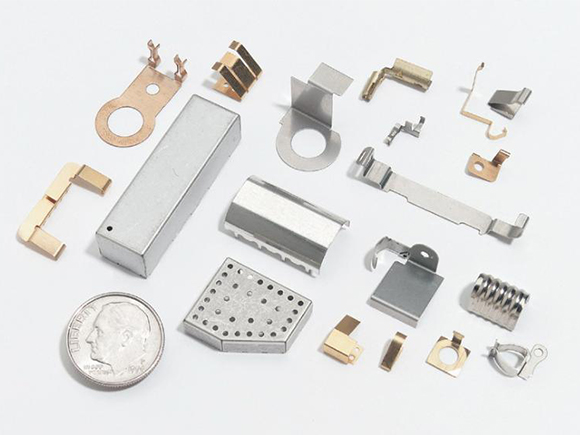

| Material Capabilities | Aluminium, Kuningan, Perunggu, Tembaga, Logam Hardened, Logam Mulia, Stainless Steel, Paduan Baja |

| Micro Machining or Not | Micro Machining |

| Bahan | Aluminum alloy 6063, 6082, 6061 |

| Warna | Color Availale |

| Ukuran | Customized Size |

| Finish | Anodized / polish / brush |

| Aplikasi | Industrial / Auto |

| Layanan | OEM yang disesuaikan |

| Usage | Field Parts |

| Processing Way | CNC milling, CNC lathe, Drilling, etc |

| Sertifikat | ISO19001 |

| Paket | Kantong plastik & karton; Kebutuhan pelanggan |

Keuntungan bergantung pada Essai

1. Produk die casting aluminium ditawarkan dengan harga bersaing.

2. Kami mengkhususkan diri dalam komponen paduan logam kecil selama lebih dari 14 dekade sekarang.

3. Kami mempekerjakan para profesional terbaik dan teknik modern untuk membuat paduan pengecoran aluminium dan produk lainnya.

4. Kami menawarkan layanan di berbagai industri seperti perangkat keras, komputasi, perawatan kesehatan, dan otomotif.

5. Produk kami dijamin memberikan reputasi yang baik dan kami berpegang pada standar kualitas yang tinggi.

6. Kami melakukan pengujian ekstensif terhadap produk.

7. Lebih dari satu solusi dimungkinkan dalam organisasi kami.

8. Ide dan desain Anda akan diberikan definisi baru oleh para ahli kami.

- Rapid Injection Molding – A low-cost rapid mold can be used for a small number of parts for a low cost.

- Digital Light Processing – It has good tolerance to the design and has a good surface finish.

- CNC Machining – An ideal choice for plastic without costly tooling. It holds tighter tolerances and has a better surface.

- Selective Laser Sintering (SLS) – SLS is for plastic prototypes with intricate internal designs.

- Laminated Object Manufacturing – A good option using thin laminates laid layer by layer for plastic. The designs should not be complex, but LOM is a low cost compared to others.

- Selective Laser Melting (SLM) – SLM is the preferred option for parts requiring high strength, high durability, and complex intricate design.

- Fused Deposition Modeling (FDM) – FDM includes a low cost, ease of us, and using multiple plastic types and colors in one prototype.

- Stereolithography (SLA) – good for low volume production parts with a quality finish and increased strength.

- Binder Jetting – A big advantage in making multiple parts at one time at a lower cost.

KASUS YANG SAMA

Memberikan dukungan perangkat keras teknis untuk perusahaan di berbagai industri.

Tidak cukup tahu?

Selamat datang untuk menghubungi kami Dan Mulai Bisnis Anda Sekarang!

Kantor : No.72-6, Jalan Selatan Huanguan, Distrik Baru Longhua Shenzhen, 518110 Cina

Pabrik : No.333 Xiangmang West Road Kota Qingxi, Dongguang, Cina