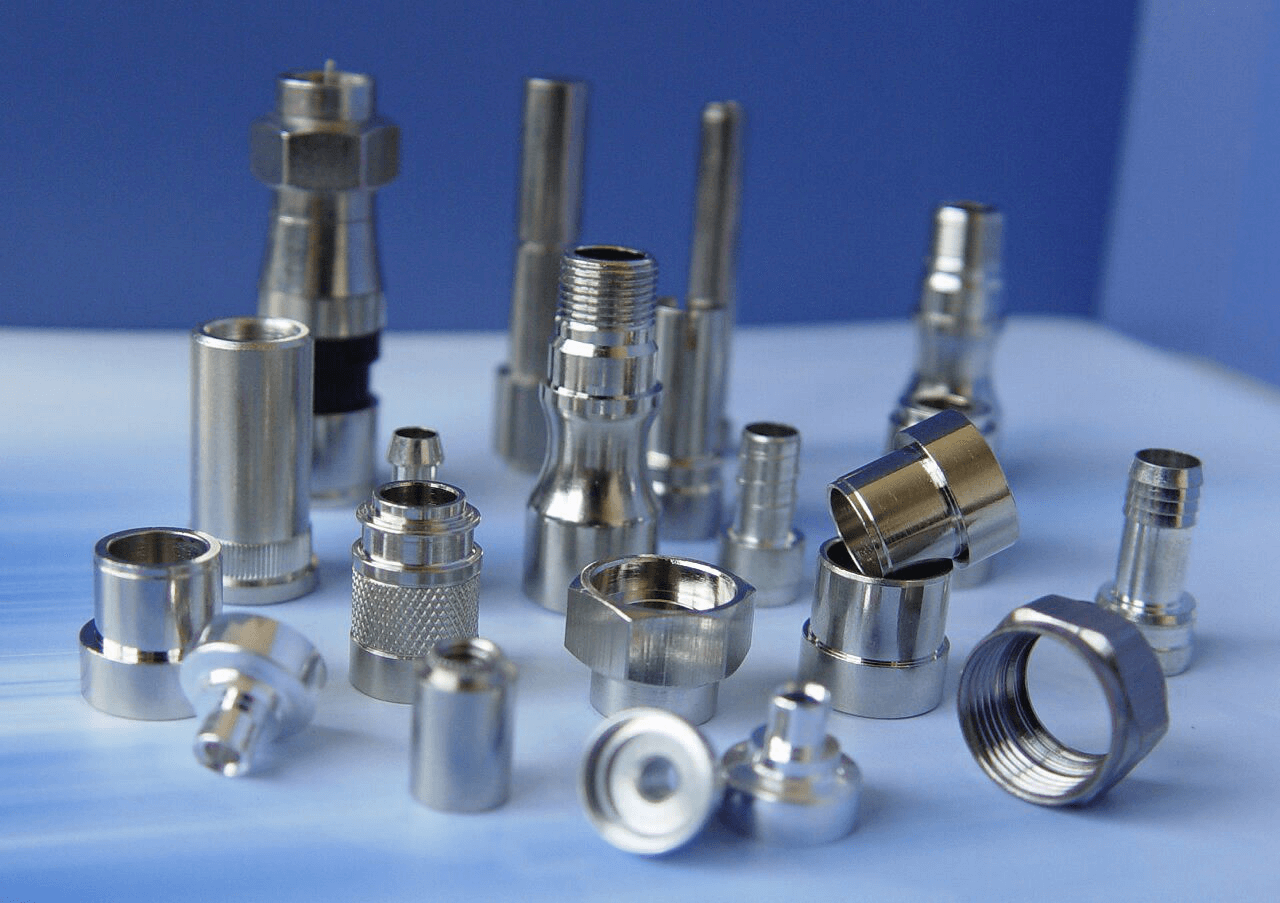

Was ist ein CNC-Rapid-Prototyp und CNC-Metallteile?

CNC Rapid Prototype & CNC Metal Parts sind im Grunde die Methode zum Entwerfen und Generieren der funktionierenden Prototypen mit Hilfe von 3D-Modellen. Das Rapid Prototyping verwendet im Allgemeinen zwei Arten von Technologien, wie z.

- Die CNC-Bearbeitung

- 3d Drucken.

Darüber hinaus können Ingenieure mithilfe dieser schnellen Prototypen verschiedene Arten von Ideen und Theorien testen. Darüber hinaus sind diese schnellen Prototypentests sehr einfach und kostengünstiger.

Hence with the use of CNC rapid prototyping, you can easily manufacture real and physical products for small home industries to huge manufacturing industries. Furthermore, you can check the functioning and tooling with the help of prototypes before making any simple product to a complex one.

Which kind of materials is used in CNC-Rapid-Prototypen und CNC-Metallteile ?

CNC Rapid Prototype & CNC Metal Parts generally have the ability to fabricate the shapes and complicated designs from the following materials. And these materials are:

- Aluminium

- stain less steel

- Holz usw.

Moreover, if you want to start your own project, then you just have to order some online service. Hence, it is not necessary for you to invest in major CNC machines.

What is the procedure to order for CNC Rapid prototype & CNC metal parts?

The online services of CNC machines simply work when you send an online order of your target products. And there are many different kinds of formats which are supportive and helpful.

These online service providers will collect the designs that you order and transform it in the prototypes of your design. These service providers have the responsibility to provide you perfect CNC-Rapid-Prototypen und CNC-Metallteile. And these prototypes are very easy to apply and they are also very affordable and profitable for beginners.

Hence, you can easily receive the products of great quality on which you can trust.

From where you can order for CNC Rapid prototype & CNC metal parts?

As all of us know that CNC services which are online providing their services perfectly. Hence, you have no need to catch the local suppliers in order to develop the prototypes of your final products.

There is also possibility of occurring the faults as they may be not well skilled. And hence you have to suffer a lot as you are also a beginner. But online CNC Rapid Prototype & CNC Metal Partsservices also offer you a lot of options when we talk about budget.

So, you can easily select the packages of your requirements which also satisfy your budget. We all know that these service companies will provide their best assistance for your ordered products. Because there is an environment of competition among all online services.

Daher gibt es keine Chance, auch nur einen einzigen Fehler zu machen. Und sie sind auch kostengünstig, da Sie auch nach Bearbeitungs- und Versandkosten problemlos erhebliche Beträge einsparen können. Darüber hinaus ist es sehr komfortabel und einfach, mit diesen Online-Prototypendiensten zu arbeiten, da die Entwurfsdateien tatsächlich systematisiert sind.

Es gibt jedoch einen einzigen Nachteil dieser CNC-Rapid-Prototypen und CNC-Metallteile , und dies ist die Versandzeit. Wenn sie Standardversand verwenden, dauert es in der Regel insgesamt 7 bis 14 Tage. Und nach dieser Zeit liefern sie Ihre Bestellung offensichtlich vor Ihrer Haustür.

Es steht Ihnen jedoch frei, Ihre endgültigen Prototypenentwürfe bei jedem besten Anbieter zu bestellen, der auf zwei Arten am besten zu Ihnen passt:

- Lieferzeit

- Kosten

Wie CNC-Rapid-Prototypen und CNC-Metallteile services do rapid prototyping for bulk production?

Although all CNC machines have ability to fabricate and create complicated designs from a file of designs. So, there is basically not any type of limitations to fabricate or create a complex design of your needs. These CNC machines actually have the ability to handle any complexity.

Furthermore, these modern CNC Rapid Prototype & CNC Metal Partsmachines have the ability to produce one-off items with great accuracy and perfection. But CNC machines are basically designed for rapid prototyping of bulk production.

And for best prototyping you can make use of some other advanced technologies. Hence, 3D printing technology will be the best to create molds for the purpose of mass production. There is a demand of CNC technology in order to generate custom tooling for bulk production.

By using CNC technology, you can achieve your desired production molds with unbelievable precision and certainty. Furthermore, your ordered prototypes of final designs will have the high quality as well as perfect accuracy.

How in some cases CNC-Rapid-Prototypen und CNC-Metallteile not perfectly suit to several prototype projects?

Wenn wir über ein ideales Projekt sprechen, besteht die Möglichkeit, dass sogar innerhalb eines einzigen CNC-Zyklus alle Prototypen hergestellt werden. CNC-Metallteile ermöglichen grundsätzlich die Erstellung aller Prototypen in nur einem Zyklus. Die Ingenieure erwarten jedoch die gleichen Ergebnisse von der 3D-Drucktechnologie. Die Hauptmaterialien, die sie verwenden, sind wie folgt:

- Aluminium

- rostfreier Stahl

- Holz usw.

Durch die Verwendung dieser Technologien können sie in nur wenigen Stunden komplizierte Designs herstellen oder erstellen.

Es gibt aber auch ein Problem bei der Bearbeitung mit CNC-Maschinen. Leider gibt es mehrere Prototypenprojekte, die tatsächlich manuell bearbeitet werden müssen. Durch die manuelle Handhabung vervollständigen die Ingenieure die manuelle Behandlung. Weil sie nicht mit CNC-Maschinen entwickelt werden können.

Daher kann bei der Blechherstellung die Verarbeitung nicht zur Laufzeit der CNC abgeschlossen werden. Daher kann die Verarbeitung von CNC-Maschinen im Vergleich zur manuellen Handhabung für mehrere Funktionen eingeschränkt sein.

Was sind einige Vorteile von CNC-Rapid-Prototypen und CNC-Metallteile ?

Der Hauptvorteil des CNC Rapid-Prototyps gegenüber dem 3D-Druck besteht darin, dass die Materialbeschränkungen geringer sind. Der große Vorteil von CNC-Maschinen besteht darin, dass die Ingenieure damit Prototypen mithilfe einer Vielzahl von Metallen und Kunststoffen herstellen.

Und diese Materialien sind:

- Kupfer

- Aluminium

- Stahl

- Messing-

- Titan

Viele andere Materialien sind:

- Schaum

- Holz

- Glasfaser

Although there is a vast variety of materials which are available for plastic 3D printing. And many of them also have the great quality of durability. Hence, engineers use CNC Rapid Prototype & CNC Metal Partsto bulk of production. Because other materials do not even permit them for functional testing.

Some advantage of CNC Rapid Prototype & CNC Metal Partsagainst 3D printing

The technology of Metal 3D printing which is actually famous as the name of Direct Metal Laser Sintering or (DMLS), has using rapidly by various companies. And it is also very successful technology for the following, like:

- aerospace industries

- Automotive industries.

And it is also famous with the name of Selective Laser Melting (SLM).

Although these 3D printers are very expensive. And these printers have also ability to design prototypes for complicated parts. Because engineers cannot create them by CNC machines. And they cannot substitute by CNC machining for whole parts.

But both of these techniques are part and parcel in order to create a CNC Rapid-Prototyps. And also, for creating prototypes for final production parts.

There is also a great advantage of CNC machining is that it has the ability to remove massive amount of material rapidly with a great precision. And the other key benefit is its ability of tight tolerances.

Es ist Standard, wenn wir mit CNC-Maschinen +/- 0,01 mm erreichen. Maschinen mit 5 Achsen können jedoch +/- 0,005 mm erreichen. Um diese Effizienz mithilfe eines 3D-Druckers zu erreichen, muss die Schicht jedoch unter 0,005 mm liegen. In der Folge bedeutet dies, dass selbst ein sehr kleiner Teil sehr lange gedruckt werden muss.

Wie CNC-Rapid-Prototypen und CNC-Metallteile mit 3D?

Wenn Ingenieure wirklich von CNC-Rapid-Prototypen und CNC-Metallteileihr Verfahren zur Produktentwicklung in einer Umgebung mit starkem 3D erfolgen. Auf diese Weise können Ingenieure das 3D-Modell in Daten umwandeln, um mit geringstem Aufwand Prototypen zu erstellen.

Glücklicherweise mangelt es nicht an Designapparaten für 3D-Produkte, um Ihnen zu helfen. Andere Tools wie:

- Renderer arbeiten

- CAD

Smoothly attach with each other. And also permits engineers to move from one technical design into 3D prototyping with an identical procedure. In order to fabricate CNC-ready models very easily two tools are required like:

- modules

- plugins

So, just work with your best service providers in order to understand the style which you want to use for rapid prototyping. And you can get help from good service providers in order to fabricate for best outputs.

Best things you need to know about CNC-Rapid-Prototypen und CNC-Metallteile

These are the things you need to know about CNC-Rapid-Prototypen und CNC-Metallteile and 3D printing for rapid prototyping.

Here are some important things you must need to understand about 3D printing and CNC for the purpose of rapid prototyping. When you will get complete information about the latest and advanced technologies, you can easily design the products that customers will surely love.

Many people believe that rapid prototyping and 3D printing are same. Rapid prototyping is basically a rapid and also very cost efficient. They are used to test, design and verify before you make the final development in your final products.