6 incredible Custom aluminum extrusion Benefits (custom extrusion 2020)

2020-10-02What is Custom aluminum extrusion?

Basically, custom aluminum extrusion is a complex procedure. Manufacturers use to create items of a fixed cross-sectional profile.

It reduces amount of machining. In other words we can say that it generates products fast. Hence it saves time and reduces cost. It results,

- consistent, firm and stable products

- reduces the waste of material

- has full proprietary control over the design

- faster the manufacturing process

Why aluminum extrusion?

There is no need to buy extra plate stock sizes and the same bar. You can reduce the waste by buying only the amount of material which you need. Aluminum extrusion is actually a very important application for all the manufacturers.

It can help all the companies which are looking for affordable and faster product development.

Custom aluminum extrusion parts are best for following applications

- curtain walls

- door frames

- sun shades

- windows

Moreover, custom extruded profiles are perfect choices for you if you are looking for something distinctive and unique. These products provide you countless opportunities to excite your experience. The resulting components are,

- extremely reliable

- durable

- different in shape and size and simply adaptable according to your requirements.

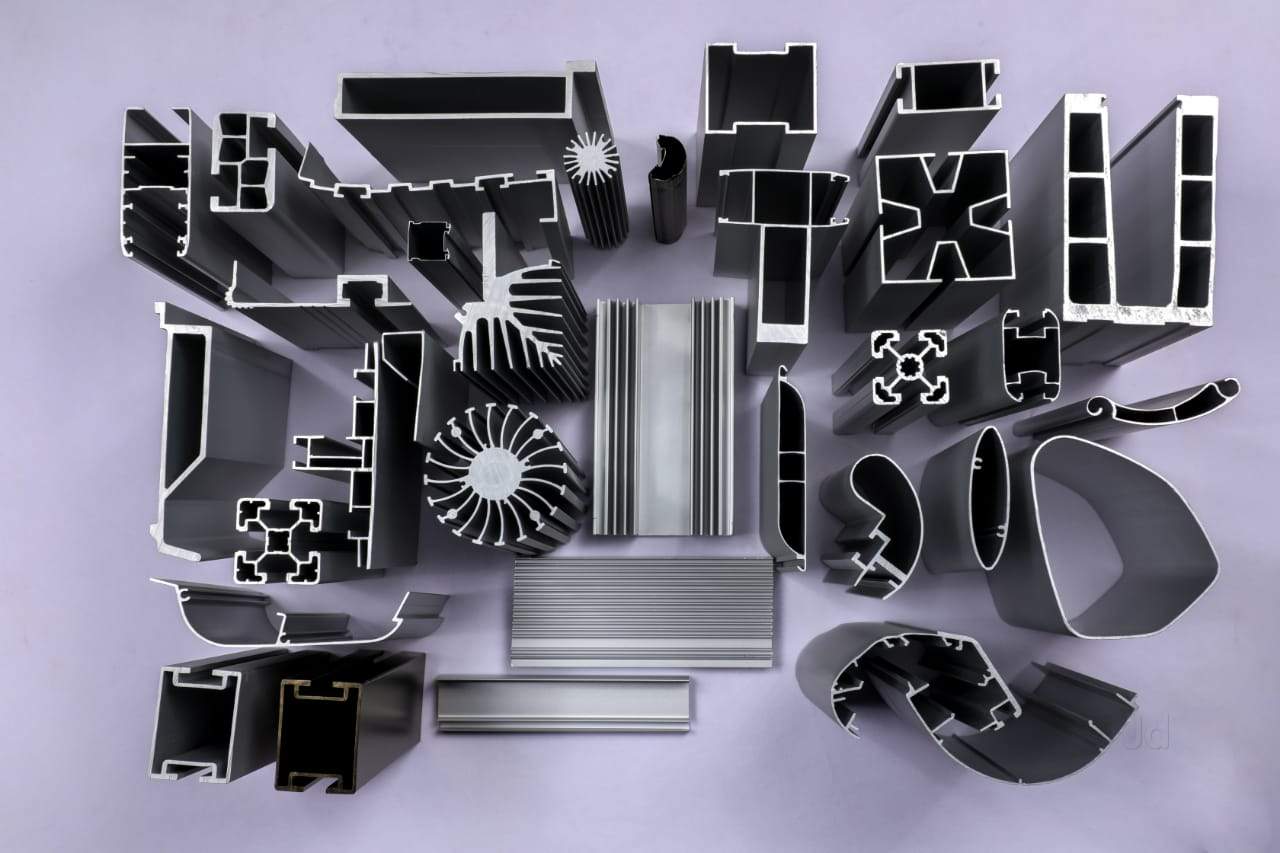

The biggest advantage of aluminum extrusion is to create complex products according to given length. Custom aluminum extrusion can also create vast variety of aluminum designed and grades with high precision. Moreover, it also has capability to manufacture products with a wide range of finishes.

How aluminum alloy is helpful in aluminum extrusion?

They can use several different materials in this process of extrusion, like

- metals

- ceramics

- modeling clay

- polymers

- concrete

- foodstuffs

Custom aluminum extrusion produces accurate aluminum cross-section shape. Nowadays the development of custom and standard aluminum extrusion has made specific innovations in our daily lives. Even it is famous in America. There companies are following this technology to make different products.

How does aluminum extrusion work?

In this process, manufacturers process and form the aluminum. It is to fabricate the products, parts and various components. Moreover, these products come to the market in variety of shapes.

No doubt regular extrusion has a lot of benefits. But custom aluminum extrusion gives you specific advantages. You can manufacture custom products. It means, this process provide great customization.

Furthermore, it has a lot of benefits in comparison to the others. It is popular for its following features,

- strength

- weight

- corrosion resistance

- durability

- low maintenance

- finish options

How does custom aluminum extrusion assist product designers?

Aluminum as a material gives great versatility. It has ability to help architect and product designers to get desired targets. Such feature we cannot expect from steel or other metals. Furthermore, aluminum is greatly recycling material and reduces the purchase weight.

In addition, aluminum extrusion can generate products for both industrial and consumer markets. We use these products or components in

- automotive

- telecommunications

- electronics

- mass transit

- industries of renewable or solar energy

6 Incredible benefits of Custom aluminum extrusion

Manufacturers create aluminum extrusions by compressing the metal under a very high pressure till it turns into a specific shape. Furthermore, manufacturers use these final components or products in several different manufacturing processes according to their needs.

Actually, aluminum is very comfortable to use and hold in different manufacturing projects. And it is very easy to customize aluminum extrusions. Extruded aluminum products are helping by creating a great ease in our daily lives.

Basically, custom aluminum extrusion is durable in comparison to the products which manufacturers make using steel, plastic or another alloy. Hence, the reason behind is, aluminum is incredibly strong and is corrosion resistant.

Furthermore, there are several advantages of Custom aluminum extrusion over other metals. Because aluminum is an ideal choice to use and manufacturers can get many advantages.

These are:

Long life service and durability:

In fact, aluminum extrusion is durable and long lasting in comparison to components which have made from other metals. Additionally, aluminum is very strong and corrosion resistant. Basically, aluminum has capability to adjust in both cold or hot temperatures.

Hence, it is an ideal choice and you can use it in any environment. So, by using the aluminum extrusion, it is very rare that it will disappoint you in any circumstances. In fact, aluminum is a metal which gives you, your money’s worth, no matter what it was.

Custom aluminum extrusion is environment Friendly:

Nowadays everyone is becoming more conscious about our planet's environment. So, it is very necessary for us to use environment-friendly material and reduce greenhouse gasses. Basically, Custom aluminum extrusion is greatly favorable for our environment. One of the best facts about aluminum is, you can easily recycle it without damaging its fundamental properties.

Furthermore, its mining process is same as the other metals. Aluminum is 100% non-toxic and you can fully recycle it without any hassle. For recycling it, manufacturers melt it down and then they make aluminum billets with this molten metal.

Moreover, they use it for aluminum extrusion. But for all the above process aluminum needs only a small fraction of energy to fabricate.

Economical Friendly:

People who do not like to spend more on materials of buildings; they must contact with Custom aluminum extrusion’s dealers. Since, aluminum is reasonably reliable and low-cost. Moreover, this is very efficient and affordable with extremely ideal features.

Its price is really effective because it is one of the plentiful metals on the earth. Additionally, it also takes less time and money for its die casting.

Extreme Versatility:

Aluminum extrusion has capability to meet the exact requirements of the designs. Manufacturers can easily shape it according to their customers’ exact specifications. It provides its manufacturers the ability to create the shapes which their clients imagine to create.

Moreover, its manufacturers can add further more operations to give it the final adorable and innovative shapes. And it also helps its manufacturers to reduce the labor cost because its assembly process is easier than other alloys. Hence, it offers extreme versatility with reasonable prices.

Custom aluminum extrusion is highly profitable to Industry:

It is one of the best metals for your tight budget projects. You can get it very easily at low prices. It is greatly recycled and you can use it without spending extra money. Furthermore, it is very easy to handle and create designs in Custom aluminum extrusion. Additionally, it reduces the labor cost.

The following coating solutions are very easy to add at aluminum fabrication shops for final protected finishes like,

- painting

- powder-coating

Characteristics of lightweight

Aluminum extrusion is relatively easy to handle. Moreover, it is very lightweight in comparison to

- copper

- iron

In fact, aluminum will be your best choice when you need weight reduction in your applications. Such as, for transportation and moving parts.

Conclusion:

Custom aluminum extrusion is excellent electrical conductor. Because, aluminum is twice conductive when we compare it for pound to pound.

Hence, it is also a great choice for using electrical connectors and bus bar distribution parts. Furthermore, aluminum extrusions are highly cost-effective. And they will be your first choice even for your low budget projects.