CNC Rapid Prototype

2020-05-25CNC Rapid Prototype

The idiom rapid prototyping is usually confused by many people with the additive manufacturing or 3D printing. However, as the name validates, Rapid Prototype is simply a method of fabrication of parts in a cost-effectively and quick manner. Prototypes are models used to verify, assess and test a new design before it can proceed to the subsequent stage of product expansion stage. Rapid prototype is not only affordable but also widely available as a result of a recent advancement in 3D printing technology. However, there are various types of quick prototype techniques that, in some instances, have proven to be more advantageous over 3D printing.

For example, CNC rapid prototype machining produces better-finished products in addition to being the most time and cost-saving technique. These benefits are the ultimate objective of any modern product development process. Remember, the choice for the most appropriate process approach depends on which type of prototype you need. If, for instance, if you are looking forward to testing your design ideas in your studio or creating an identical prototype for engineers to access your products aesthetic characteristics. Moreover, it makes possible to scale and size of your identical prototypes, and then the CNC rapid prototype has manners of printing available.

What is CNC rapid prototype, and how does it operate?

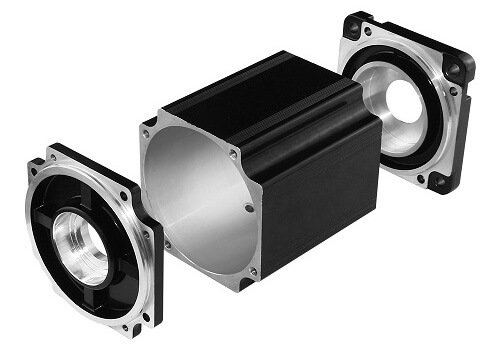

CNC is an abbreviation of the word Computer Numeric Control. It involves a set of different machines and a computer used to direct all interactions between the work pieces and the machining tools. Machining is a mechanical process that involves transforming a large amount of raw material into finished products—for instance, converting a large block into a final product through an appropriate content removing process. Such machines are computer-controlled and interact with work piece via a series of various codes known as M-codes or G-codes. These codes are generated using a commercially open software known as Computer-Aided Manufacturing software.

What are the benefits of CNC rapid prototype production?

It is true to say that CNC machines have greatly revolutionized most of the manufacturing industries in the 21st century. Some of the advantages of CNC machines include the following.

1. Matchless precision.

With CNC rapid prototype production capacity, all of your products' accuracy is fully guaranteed within a thousand divisions of an inch. The 3-axis machine is the main form of the CNC machine, which has its axis moving alongside the x, y, and z-axis when cutting various parts. The modern and advanced 5-axis machines have the capacity to spinning on both sides of the device, thus enhancing efficiency. The CNC's ability to create complex parts and with exceptionally tight tolerance to make accurate prototype and parts, thus making it suitable for both low and high volume productions.

2. It takes 24 hours production possible.

Unlike human workers, CNC rapid prototype production can work around the clock without taking breaks in-between and maintaining the highest accuracy and consistent quality. Such production makes it possible for the factory ability to produce in bulk, thus meeting the existing demand on its products within a shorter period and thus increasing its sales.

3. It makes it possible for scalability and mass production.

CNC rapid prototype machines are the ideal choices for bulk production of identical parts. Once the data is feed on the devices, they can run for 24 hours performing the same operation and without further instructions. For example, using CNC machines using CNC machined aluminum as the raw material for production makes it easy for your designs. You can adjust your prototype model size by your relevant factor without having to make so many wearisome calculations. All the figures you feed into your computer are automatically processed to your desired results within a second.

4. Enhanced production capacity

With the usage of multi-axis CNC machines, the production of unattainable and complex geometries has been simplified. For instance, before the introduction of CNC rapid prototype machines, the creation of complicated parts and prototypes would have been to undergo processing for multiple times since the traditional machining techniques were susceptible to many faults. Besides conventional production methods, a lot of material wastage before the introduction of CNC machines. Still, now these challenges have been tacked, thus making production more cost-effective.

Consistency in production

As discussed above, CNC rapid prototype machines can handle exceptionally higher accuracy. This is because once you update the machines data according to your design want, no more data inputs is be required. Such production makes it possible to produce identical parts without any difference correctly, and this was almost impossible to achieve when using traditional techniques.

Better safety in the workplace

Remember, any factory has the mandate to keep the safety and health of its employer as a priority. Unlike traditional production methods, CNC rapid prototype machines have a very low probability of accidents happening. All CNC fast prototype machines come with numerous safeguards to ensure maximum protection and secure working environment for your workers.

Multipurpose production

One benefit of using CNC machines is that you are not limited to a particular type of production. You have endless possibilities of output due to the advanced innovations and art features coming with CNC machines. For instance, CNC rapid prototype can perform operations that help you produce identical items with ease and accuracy. CNC Prototype machining services include;

Clear Optical Prototyping ServicesManufacturing of working prototypesIndustrial, automotive prototyping services

Aluminum machining services

CNC rapid prototype production has brought about so many industrial revolutions globally. For instance, it has enabled the creation of outstanding quality products due to their advanced capabilities. Compared to the traditional production process, the CNC rapid prototype technology has enabled the manufacturers to produce sophisticated geometries within the shortest time possible, lower production cost, and much more excellent repeatability. The cost of mass production is one of the significant transformations that CNC machines have made it possible in the modern industrial world. With the increase in the demand for the prototype in contemporary production, CNC rapid prototype machines have proven to be the best option for factories conduction such operations. Such production is made attainable because prototypes can be made using identical material and process.