What is CNC machining?

What is CNC machining? CNC machining is exponentially controlled machining, a method that uses digital information to control mechanical motion and machining processes. Traditional machining is done by ordinary machine tools operated manually. During processing, mechanical tools are used to cut metal by hand, and tools are used to measure the accuracy of products using […]

Reasons why CNC machining is widely used

Reasons why China CNC machining is widely used China CNC machining is to use the automatic control system to install digital program flow commands to control the automatic start and stop, commutation and speed change of China CNC machine tool bearings. You can choose a CNC blade, you can change the cutting amount and walking […]

What are the requirements of CNC parts processing technology?

What are the requirements of CNC parts processing technology? The rotation speed, feed speed and cutting speed of the spindle of the CNC part machining center are mainly determined by the tool, and the setting amount of different tool parameters for processing the same material is also different. However, the tool will provide the parameters […]

What are the reasons for errors in CNC machining parts

What are the reasons for errors in CNC machining parts During the operation of the CNC machining parts center, there is a certain gap between the screw and the nut. As the operating time of the equipment increases, the gap gradually increases due to wear. Therefore, the corresponding gap compensation of the reverse movement is […]

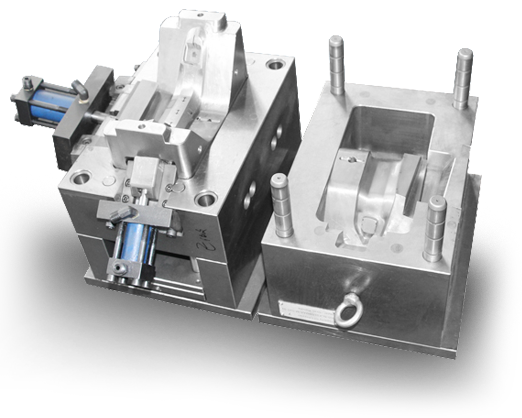

Designing plastic molds involves three steps

Designing plastic molds involves three steps The design of plastic molding dies requires a preliminary analysis of requirements and multiple content discussions. If the demand analysis is not accurate in the early stage, it will directly affect the quality of mold design. Therefore, the design process of plastic molding dies must be standardized and improved. […]

If these problems occur in CNC machining, how to deal with them?

I encountered some abnormal conditions during the CNC processing. If I should deal with it, now I will share it with everyone ~~ First, the workpiece is overcut: the reason: 1, the knife, the strength of the tool is not too long or too small. Causes the tool to bounce. 2. Improper operation by the […]

Programming tips in CNC machining of aluminum products

Programming tips in CNC machining of aluminum products Programming is an indispensable step in the CNC machining of aluminum products, but many novices do not understand CNC machining programming. When programming and operating machining, it is necessary to avoid collisions in the CNC machining center. Next, I will share some tips about programming in CNC […]

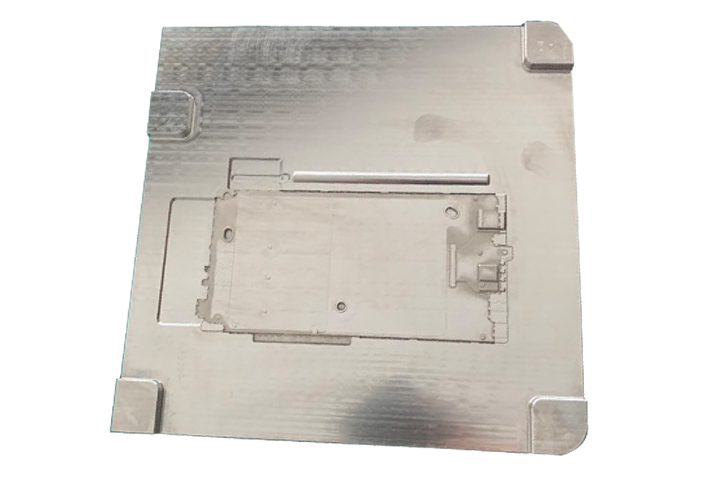

What are the steps in the mold processing process?

What are the steps in the mold processing process? The mold processing process is from cutting to processing and finishing. Established is a hardware and plastic mold manufacturer. I will share it with you and hope to help you. Cutting material: front mold material, rear mold material, insert material, row material, inclined top material; Open […]

How to learn how to clean plastic molds

Any product needs to have correct maintenance knowledge, and mold products are no exception. As a key process of mold maintenance and maintenance-mold cleaning, it has a very important impact on mold maintenance. Jiehui Chuang Xiaobian will share some plastics Knowledge of mold cleaning. 1. Standardized cleaning procedures Systematic mold maintenance is based on maintenance […]

How to understand the basics of plastic molds

The plastic mold includes a cavity with a variable cavity composed of a cavity combination substrate, a cavity component, and a cavity combination card. A convex die with a variable core composed of a side-section composite plate. Plastic mold processing plays an important role in the release of new industrial products. Today Jiehui Chuangxiaobian will […]