How to learn China CNC machining & Machining CNC Auto Parts skills in 2020?

2020-07-20What is China CNC machining & Machining CNC Auto Parts?

China CNC machining & Machining CNC Auto Parts are basically a procedure of manufacturing the CNC machining parts. And in it manufacturers use computer software that is pre-programmed.

This software actually controls all the movements of factory machinery and tools. And this process generally has the ability to use and control a wide range of complicated machinery. Hence, this CNC machinery can be as follows:

- lathes

- grinders

- routers

- mills

Furthermore, in a single set of hints, for three-dimensional tasks of cutting and fabricating. The manufacturers can consummate CNC machining parts easily with CNC machining. In fact the CNC process works inconsistent with the terms of manual control.

As we know there are some limitations of manual control. That requires operators to guide the following parts of these machining tools immediately. Like:

- Buttons

- Levers

CNC is actually a short form of “computer numerical control”. Visually, CNC machining system may have resemblance with manual set of computer components. But the consoles and software programs in the China CNC machining & Machining CNC Auto Parts have distinguished it from all other different types.

China CNC machining & Machining CNC Auto Parts market cross the 100.9 billion worldwide by 2025

Nowadays, almost all type of industries has made use of CNC machining within their process of manufacturing. And the reason behind it is that, it facilitates a broader and larger scope of applications. When we do a comparison of manually operated machinery with CNC machining.

Another cause of using China CNC machining & Machining CNC Auto Parts is that it boosts and increases the production level.

Furthermore, there is also a wide range of jobs that is enough to surprise you. But in the condition that you are also searching for a flawless career, you must take a deep knowledge about several paths. Hence, by doing so you can easily discover something really beneficial just like CNC machining.

So, with the increasing activity in the industry of China manufacturing, is increasing an in the opportunities of job. Manufacturers are estimating that for upcoming seven years almost 56, ooo jobs are expecting in the field of CNC machining.

And it is the perfect time to research and analyze this most thrilling, rewarding and impressive path of career.

How do China CNC machining & Machining CNC Auto parts work?

China CNC machining & Machining CNC Auto parts work fully automatic. Basically they need only one thing and that is digital files. These digital files actually have all the directions about cutting tooling and trajectories. These machining procedures generally require several instruments in order to generate a specific part.

Manufacturers have the ability to build the libraries of digital tools. These tools actually interact with the physical machine.

This type of machinery has work ability to execute automatically. For working automatically, CNC machines have switch tooling process. And it is based on the digital directions which help them to make manufacturing workhorses.

Furthermore, in these CNC machining & Machining CNC Auto parts operations actually start with the designing parts. And these designing parts have designed in CAD software. The model of 3D actually identifies the necessary elements of the final part like:

- dimensions

- properties

Several programs of this type occur in CAD-CAM packages. So that the overflow can persist in the similar programs. In the condition that CAM and CAD come in similar family of the product, then there is basically no need of any files translations.

On the other hand, these CAD files have the requirement to import. The software of CAM basically develops the model for the entire procedure of fabrication.

There are actually four main parts of this process of fabrication

First:

It checks and interprets for the errors in the model of China CNC & Machining Auto part

Second:

It helps to create a CNC program in order to create the physical parts of the program.

In short this program is a complete set of integrates which actually gives the guidance to the cutting head in the whole process of manufacturing.

Third:

In the third step manufacturers select the correct and appropriate parameters. And in these parameters following are included:

- voltage

- cutting speed

- RPMs, etc.

Furthermore, its configuration totally relies on the geometry part and along with available tooling and machinery.

Fourth and last main part:

In this last step manufacturers establishes and decides the final nesting. The term nesting actually means that placements and location of the final parts with respect to their related material. The main purpose behind it is, make the most use of related material.

How many types of China CNC machining & Machining CNC Auto parts are?

There are basically many unique and exceptional types of CNC machining & Auto parts. In most of these machines, the elementary functions are same. But they are designed according to their functions that they have to perform.

Here we are giving some examples of CNC machines. These are:

- Lathes

- CNC Mills

- Plasma cutters

- Sinker electronic discharge machines

- Wire electronic discharge machines

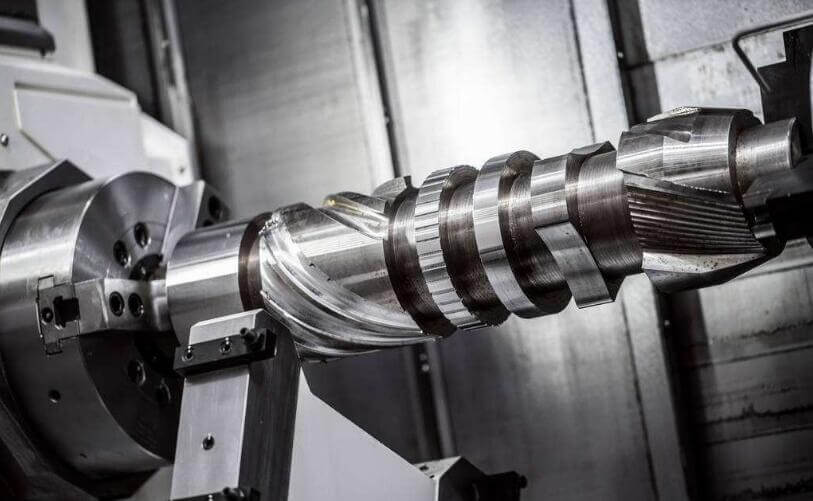

Lathes

A lath basically has the ability to cut pieces in the circular direction. The manufacturers in this machine do this special process with the help of indexed tools. Manufacturers use lathes in order to fabricate complex designs. But lathes are basically not complex machines.

CNC Mills

Manufacturers run these types of China CNC machining & Machining CNC Auto part with the help of programs. These programs have made hints and that can use the both

- letters

- numbers

These mills mostly use three-axis system. But latest models of these mills are extra complex. And they actually have the ability to operate six-axis system at a time.

Plasma cutters

Manufacturers use plasma cutter CNC machines mostly for materials of metal. As they know that these metals need a lot of heat and speed for making precision cuts.

Here are details of remaining types of China CNC machining & Machining CNC Auto parts

Sinker electronic discharge machines

It is also known as sinker EDMs. They work just like wire EDMs. In this process, the difference is between how electricity is used to remove pieces. With the help of sinker EDM, for the purpose to conduct the electricity manufacturers soak the materials of metals into a dielectric fluid.

Furthermore, in this process of China CNC machining & Machining CNC Auto part, we see that how manufacturers mold the pieces of metals into certain shapes.

Wire electronic discharge machines

This type is also famous with the name of wire EDMs. In this type of machines manufacturers use electrical sparks in order to mold pieces in certain shapes.

What are some of the advantages of China CNC machining & Machining CNC Auto parts?

Here we are providing you some helpful advantages of CNC machines and Machining CNC Auto parts.

These are:

- Parts may have customization or alteration

- Higher precision

- Costs of set up are fairly low. so functions can rush and set once again

- Lower inclined to inner stress in comparison to other processes because parts have great physical qualities

- For progress, many changes can be applied easily and smartly inside a manufacturing run

What are the applications for manufacturing China CNC machining & Machining CNC Auto parts?

Engineers build several most familiar China CNC machining & Machining CNC Auto parts for the purpose of niche procedures of manufacturing.

For instance:

- Electrochemical machining

- Conventional CNC machines

Electrochemical machining:

Manufacturers use these CNC machining in order to cut the products of metals that have great durability.

Conventional CNC machines:

Engineers use these CNC based machines for prototyping.

Why China CNC machining & Machining CNC Auto parts are necessary?

Since we have learned that operators of CNC machines work and also help in a wide range of fields. So, people from all different stalking are getting benefits from CNC machines.

For example from military groups to hobbyists, people are attaining advantages by these CNC machines to convert raw materials in the final products in a very low cost. China CNC machining & Machining CNC Auto parts have the following qualities like:

- extra efficient

- faster and quicker

- More safer