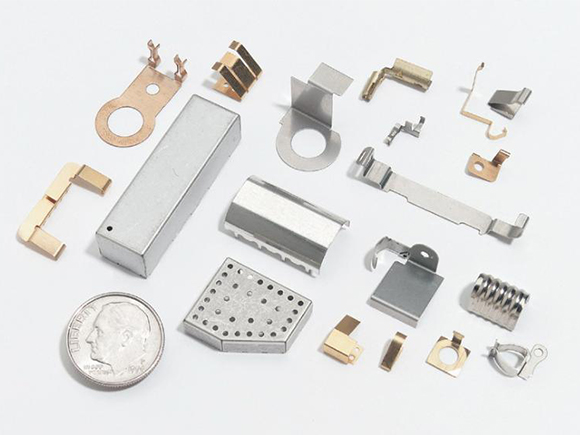

Sheet Metal Fabrication

The basic processing methods of sheet metal parts are as follows: blanking, bending, stretching, forming, and welding. This specification describes the process requirements to be noted for each processing method.

(Sheet metal, blanking, bending, stretching, forming, layout, minimum bending radius, burr, springback, dead edge, welding)

According to the different processing methods, the blanking can be divided into ordinary punching, several punching, shearing, blanking, laser cutting, and wind cutting. Due to different processing methods, the processing technology of blanking is also different. Sheet metal cutting methods are mainly digital punching and laser cutting. Digital punching is processed by CNC punching. The thickness of the sheet is processed by cold rolled sheet and hot rolled sheet less than or equal to 3.0mm, aluminum sheet less than or equal to 4.0mm, and stainless steel less than or equal to 2.0 mm