Sheet Metal Fabrication: Everything That You Need to Know

The term “Sheet Metal Fabrication” would seem alien to people outside the respective industry. The first impression would be that it is highly technical. Project requirements, processes, and terminology are not common among the general audience.

Yes, we agree that the concept does have a technical aspect to it. However, it is not like, a lame man cannot understand the basic concept of steel fabrication. All they need to have is the foundational knowledge of those methods.

Once, you have the basic information, it won’t be difficult for them to expectations that are real. They would also get an idea of when to fire a metal fabricator for their application. In the course of this article, we are going to provide you a brief introduction to metal fabrication.

Introduction to Sheet Metal Fabrication

Numerous tools come into action when you decide to hire a metal fabricator in order to create an application, product, or series of products. Moreover, you would need highly skilled professionals in order to complete the job.

These professionals along with different tools will help you achieve your target. Below, is a breakdown of what all is involved in the fabrication process of sheet metal.

Blueprints

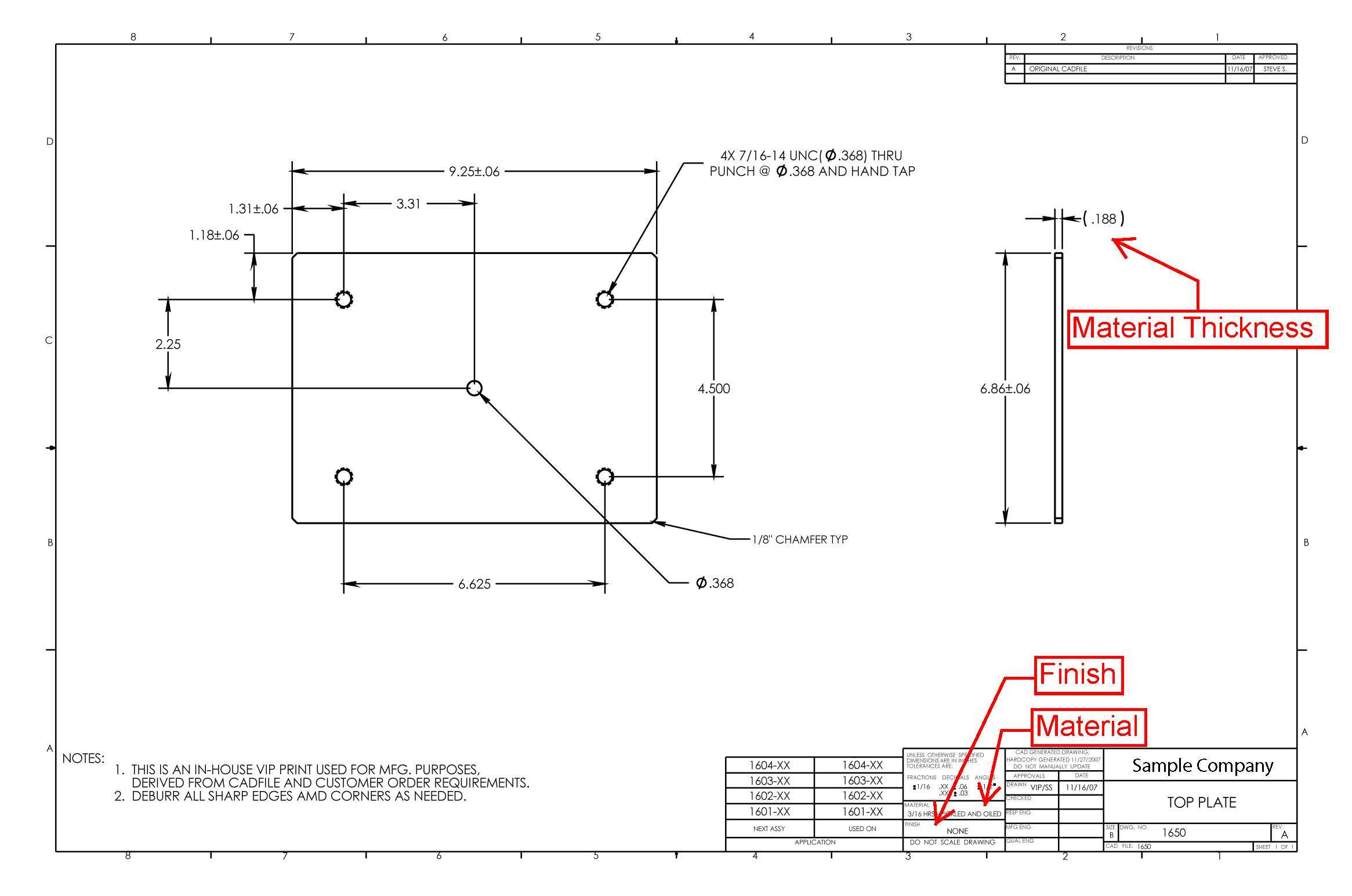

The first thing that comes into action is working with the blueprint. The engineer would spend time on perfecting a blueprint. After all, this blueprint provides the basics for the specifications of the sheet metal product. With the blueprints, you will have the essential rough drawings.

Final Shop Drawing

For the end product to meet the required requirements and specifications, it is important for the calculations and drawing to be error-proof. To ensure the accuracy of these drawings, you will have to double them.

Continuous checking will eventually lead to final shop drawings. These drawings are more than the first draft. They will contain all the required in-depth calculations regarding the sheet metal. These fabrication process uses these calculations and specifications to manufacture the desired product.

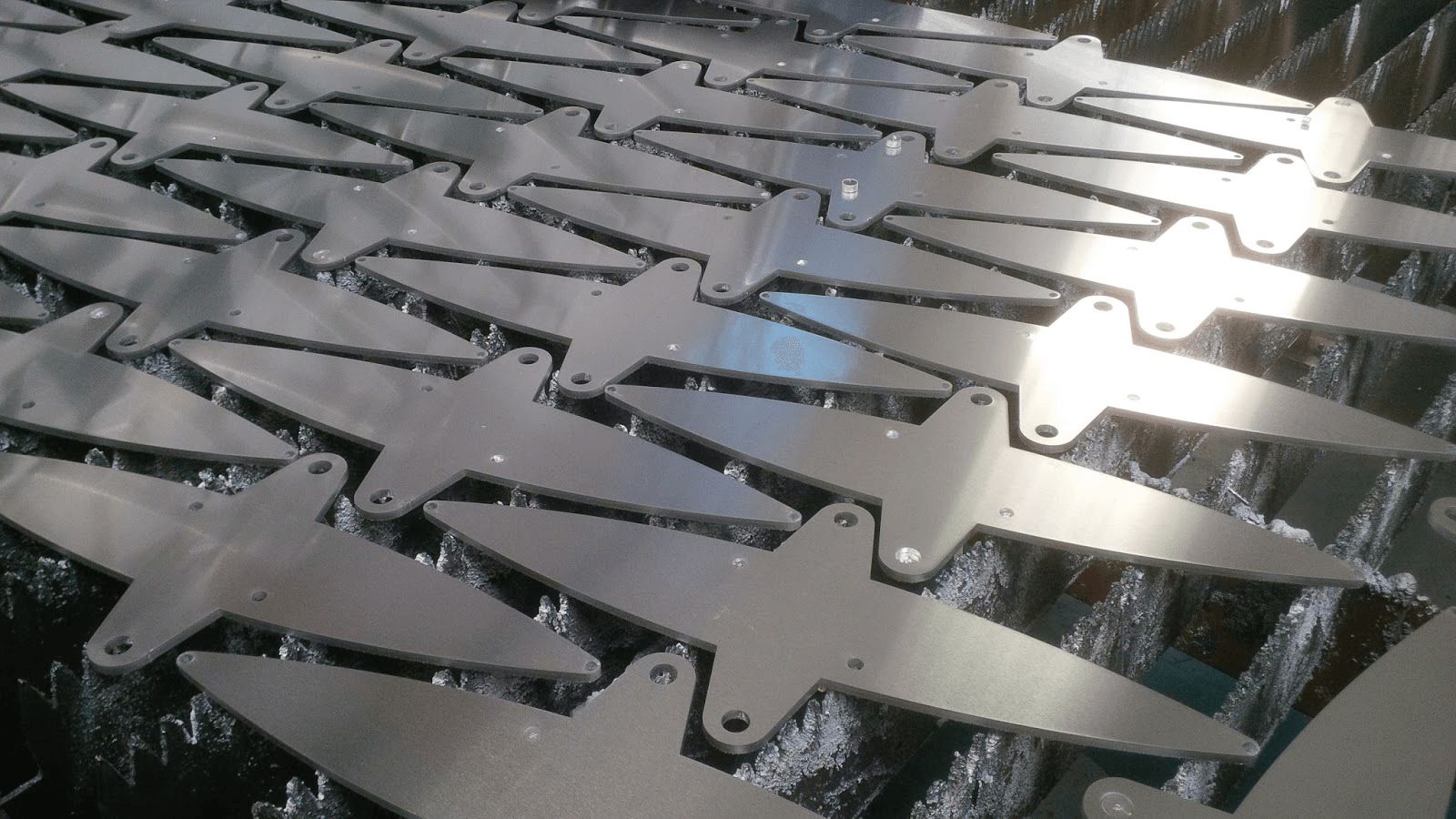

Metal Fabrication Process

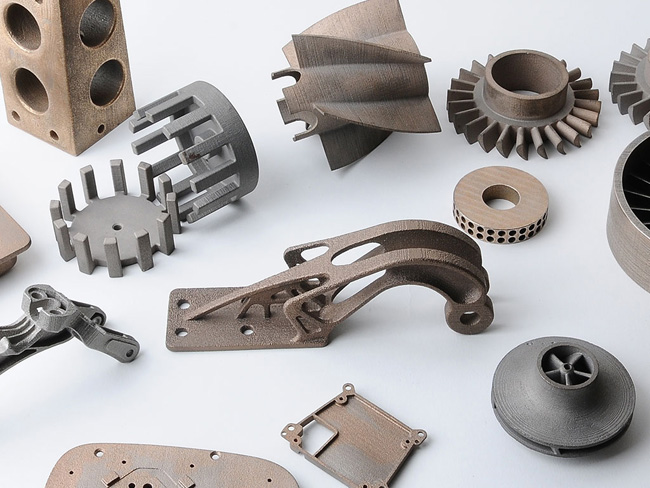

The metal fabrication process involves a couple of steps such as joining, forming, cutting, etc. We will talk about these steps in more detail below.

Product Finishing

Even after the completion of the fabrication process, the product would require additional finishing in order to use it commercially. There are several techniques and tools that manufacturers use to provide the product its final finish.

An important thing to remember here is that every step of the fabrication process needs to be handled with utmost care. Complete one step before moving onto the other one. If you rush through all the processes, you are more likely going to compromise the quality and integrity of your work.

This is something, manufacturers who take pride in quality would avoid at all costs. We hope, this general overview did help you get started. Below, we are going to provide information regarding the fabrication process in detail.

So, without any further delay, let us get started!

Metal Fabrication Overview

Cutting

The first stage of steel metal fabrication is cutting. The name itself is self-explanatory. In this step, the manufacturers fabricate the metal either in a plate or a rectangular shape. The shape greatly depends upon the thickness of the plate.

So, we can say that the first step is actually cutting the meta sheet as per your specification. It involves turning the metal sheet into the desired shape. There are two different methods for cutting the sheet.

Cutting with Shear

The first method involves using the shear force. The shear force would cut the sheet metal while using three different operations. Shearing, blanking, and punching are these three main techniques. Every operation is responsible for serving a specific purpose.

It is not possible to miss any one of these operations. So, make sure that you go through with them properly.

Cutting without shear

Contrary to cutting with shear, we have cutting without shear. We are pretty sure that the name is self-explanatory. This process is dedicated to industrial metal fabrication projects. With this, you can enjoy faster processing times as well as optimum precision cutting.

Something, that lacked in the above technique. For cutting without shear, you would have to use other tools. Such as the waterjet cutting, plasma cutting, and laser beam cutting. Every type of cutting method does come with its merits and demerits.

So, you need to analyze all these methods before you finalize on the one that would work for you. Despite the method you choose, do remember all these methods work best for large scale industrial product precision cutting.

Bending and Forming

After cutting, comes the bending and forming. Like cutting, you have several equipment and tools at hand. These tools will help you bend or form the sheets as per your requirement. In order to achieve V-bends or U-bends, you would be needing rolling machines, press brakes, or similar tools.

These tools can also cater to a number of other custom forms that you specify in your project’s blueprint. Regardless, what you use to create these bends, may it be machining, folding, stamping, do remember that this stage is important.

After all, all the transformation of the sheet metal takes place at this stage.

Joining

Joining is another important aspect of metal sheet fabrication. After all, it is vital to join the ends after you have conducted cutting, and bending on the desired metal sheets. There are several projects that require the joining of multiple parts in order to be completed.

For these projects, accurate joining is imperative. After all, you would not want those parts to fall apart once the products come into action. So, make sure to use a robust technique for the fusing of these parts. Manufacturers of use adhesives, riveting, brazing, or welding for this purpose.

Also, make sure that the welders have experience. They need to be skilled and should have the proper training to ensure precision at this stage.

Finishing

Finishing is the final stage of metal fabrication. Although, the product is almost ready, yet this stage holds great importance. After all, the overall look of the product would depend upon this stage. For a consumer base product, you would have to pay close attention at this stage.

No one wants to have an ugly product, even if it performs well. So, once the cutting, bending and forming is completed, it then joined and is ready for the final surface finish. There are several ways of adding finishing to the final product.

For finishing, manufacturers use a paint coating, powder coatings, or silk screening. These finishes also add possible sealants or similar protection layers to the product. To either enhance or improve the certain properties of the sheet metal, there are other finishing treatments available as well such as the resistance or the conductivity.

Why Choose Us?

Essaii is an excellent sheet metal fabrication manufacturer. They have years of experience in this respective field. Their vast experience makes them the epitome of their competitors. Since they take pride in delivering only high-quality products, thus they will never compromise on quality of the fabrication process.

Their highly skilled professionals would pay close attention to every stage of the fabrication process. After all, their objective is to satisfy the consumer by manufacturing high-quality products.

Take Away

The metal fabrication process is an imperative part of any product development. Therefore, it is important to pay heed to all its aspects such as cutting, bending, joining, etc. A reliable manufacturer would never try to hurry through these processes.

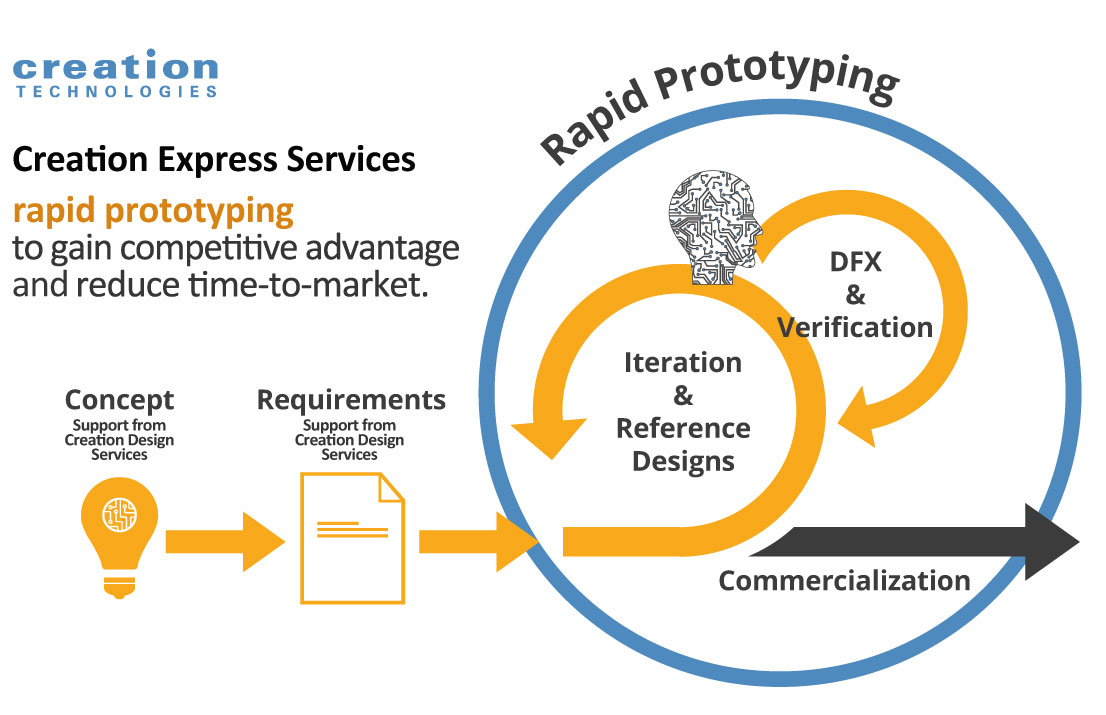

On the contrary, they would spend their time to ensure that every stage is completed in the best possible way. After all, timely correction is better than the rework. Thanks to technological advancement, we now have different types of fabrication processes as well.

So, to choose the right type of process, you would need to reach out to a component manufacturer as it would be able to provide assistance in the best possible way.