What is CNC machining?

CNC machining is exponentially controlled machining, a method that uses digital information to control mechanical motion and machining processes. Traditional machining is done by ordinary machine tools operated manually. During processing, mechanical tools are used to cut metal by hand, and tools are used to measure the accuracy of products using a calibrator. However, traditional manual processing is far from meeting production requirements.

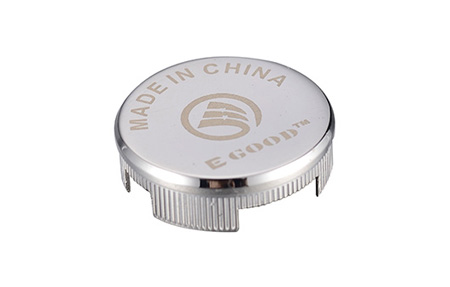

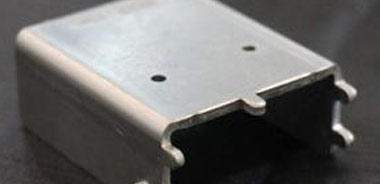

The CNC processing quality is stable, the surface texture of the finished product is clear, the metal texture is firm, smooth and smooth, without scratches and edges, and the heat dissipation coefficient of the raw material has little resistance. It will not change with precision machining. Manufacturers can adjust specific processes to improve their heat dissipation performance. For example, oxidation, stretching, cooking, sand blasting and other processes can be performed under numerical control operations.

CNC processing adopts imported equipment; the products processed by the automatic lathe parts are processed with accurate thread, no slip, tolerance up to 0.01 mm, smooth appearance, no burrs and sticky hands. CNC machining is carried out in strict accordance with the size specifications of drawings and samples. The tolerance accuracy is up to 0.01 mm. Each batch of products can be delivered to customers after 3 accuracy tests. The defective rate is strictly controlled within 1/1000.

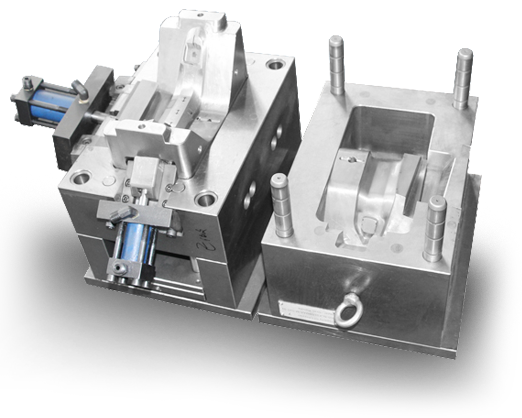

The CNC machining center automatic control system can usually control the CNC lathe to complete the automatic start and stop, commutation and speed change of the spindle bearing according to the digital program flow instructions. It can intelligently control the feed speed, direction and production processing distance for production processing. Select the size of the CNC blade and change the cutting amount and walking path to complete various auxiliary actions required for production and processing.

The structure of CNC machining CNC lathe also includes spindle bearing box, tool holder, feed transmission device, machine tool itself, hydraulic transmission system, refrigeration system, lubrication system and other parts. It is just that the feed system of CNC lathe and the feed system of horizontal lathe are essentially different in structure type. The composition diagram of the mechanical structure of a typical CNC lathe is the same.

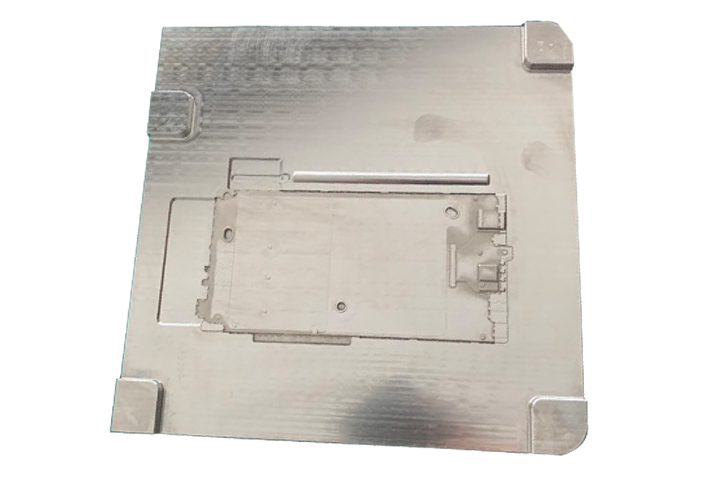

CNC machining is the process that the control system sends out instructions to make the cutter make various movements that meet the requirements. The technical requirements such as the shape and size of the workpiece and the requirements of the processing technology are expressed in the form of numbers and letters. The quality of CNC processing is stable, the surface texture of the finished product is clear, the metal texture is firm, smooth and flat, without scratches and edges, and the raw material has a small coefficient of heat resistance and will not change with CNC processing. Manufacturers can adjust specific processes to improve their thermal performance. For example, oxidation, stretching, cooking, sand blasting and other processes can be performed under numerical control operations.

In the case of multi-variety and small batch production, CNC machining quality is stable and production efficiency is high, which can reduce the time for production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the optimal cutting amount. It can process complex profiles that are difficult to process with traditional methods, and can even process some unobservable processed parts.

The above explanation is about CNC processing. I hope it will be helpful to you after reading it. If you want to know more about CNC processing, please feel free to consult customer service online or call our service hotline (upper right corner of the website). Consultation, we will wholeheartedly provide you with quality service!