Medical Precision Parts That Enhance Health

Medical precision parts must be of the highest quality, if they are to deliver the results that doctors and nurses expect. Patients rely on the expertise of manufacturers, hoping that through the use of these products, their level of wellness will increase. Proper management of the entire production process, leads to goods that satisfy all parties.

Meeting ISO standards

Medical precision parts produced by leading companies, are made in facilities that meet the guidelines of the International Standards Organization. Since the ISO 9001 standard is used globally, you can be sure that your health devices will meet the needs of any nation. These medical products can be traded with your partners overseas, and used in dental clinics or hospitals.

ISO 13485 certification standards must also be met by companies that produce parts such as dental implants. Companies that meet this standard have shown that they can produce health devices, or provide other services, that meet customer requirements.

Ensure that devices work properly

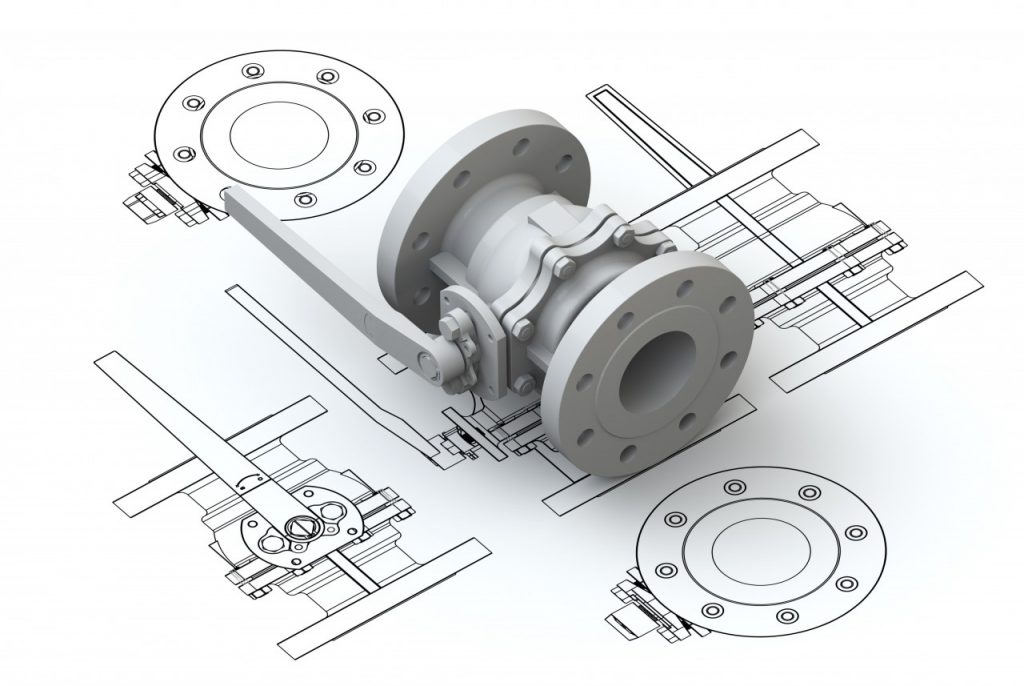

Medical precision parts are made to meet exact size dimensions. Their length, width and diameter all fit the needs of the client. None of these measurements can be even 0.5 mm out, or it could throw off an entire system.

Since accuracy in manufacturing these parts is so important, a lot of time is spent on checking this aspect of the process. You can be sure that all the parts you request for your hospital or clinic will work with the system you've established.

All the parts will be compatible with the devices you already use. This means you won't need to invest in any new machinery. If your dental office needs replacements for parts that you already use, the new ones will be an exact substitute.

Ensure patient safety

Patients are protected by regulations that cover the machining sector. They also receive protection through standards that cover the process through which orthopedic implants, and other healthcare devices are made. Manufacturers understand the risks if the wrong materials are used, or a part does not meet design specifications.

For example, if an implant is used to help fix a fracture, using the wrong dimensions can make that worse. The surgeon trusts that the implant they are supplied with is exactly what the manufacturer states. Any errors in this aspect decrease patient safety.

Implants that are well made, in this context, will support the growth and healing of fractured bones. The patient will not be in pain as long. They can get back to their regular activities in a shorter time, or at least in the time estimated by their physician.

Reduce the cost of medical treatment

Since damaged parts on equipment can easily be replaced, using CNC precision parts helps to reduce treatment costs for your patients. You can perform diagnostic procedures with accuracy, and your patients will feel at ease.

Most of the equipment used in clinics and hospitals around the world, is supplied at a high cost. Implants are expensive too. When costs can be kept within reach, good healthcare becomes more accessible.

Everyone likes feeling comfortable about their health. When doctors and nurses are able to offer medical care at a cost that patients can afford, everyone is subject to less stress.

Make new medical devices available

Lifesaving technology is constantly being developed across the world. Researchers can implement their ideas once the right parts can be provided. This helps patients to move, lift objects, and perform other tasks that they previously couldn't do.

The design process for medical parts involves several steps. Researchers and engineers in the field may develop sketches of what they need the final product to look like. They may sometimes examine or compare several ideas of the functions it needs to perform.

Several parts are used by patients daily. This means that the materials must be safe when utilized in this way. They must also perform in the same way under diverse circumstances. For example, if a patient receives a plate to help heal a broken bone, it's not supposed to cause pain at different temperatures within a normal range.

Manufacturing companies have designers who can make recommendations on the item that is being developed. They can introduce doctors to new materials that can meet their needs. Some of these are relatively inert, so they won't be damaged when in the presence of different chemicals.

In-house designers can also recommend materials that have a long life. This reduces the frequency of replacement. That helps to encourage a patient to accept a particular treatment, since they won't have to go through the stressful experience often.

Decreased risk during surgery

When a joint is being replaced, it is important that the right implants are. available during the surgery. Complications can result in unnecessary pain for the patient. The resulting trauma can discourage patients from following up on treatment.

Implants that are correctly made will put less pressure on tissues that may already be inflamed or otherwise damaged. Those that do not have the correct shape may hinder the patient's ability to perform all of their regular activities.

Surgeons who are working with the correct parts can correctly assess the patent's chances of healing. There is less risk of infection following a surgery, and less of a chance of damage to nerves or blood vessels during a surgery.

Spinal implants are going in an especially sensitive area. This type of surgery carries risks which aren't present when doctors are working on other areas of the body. The spine acts as a route for signals that are sent all over the body, and implants must be precise.

When implants used with the spine are well made, they can dramatically improve a patient's quality of life. Implants can allow a patient to regain their ability to walk around their home.

A well-crafted implant can provide adequate support in the lower back, helping to reduce pain. These devices can make it possible for older people to perform tasks that they could not before surgery. In this way, precision parts allow patients to fully live their lives as they choose.