How much Auto Stamping Parts Cost? (Equipment selection for tooling Manufacturing)

Auto Stamping Parts are common in engineering, shipbuilding, aircraft construction. Only earlier we used to carry it manually. In addition, the method gained wide popularity. Because it was possible to make everything - from a small, insignificant part, to an airplane wing.

Today's technologies and equipment allow automatic metal stamping. This process has a number of advantages, which we will discuss below.

What is Auto Stamping Parts?

There are two methods of metal processing:

- cold and

- hot

Generally, cold forging is common in producing:

- machine bodies

- aircraft parts

- and other single or multi-batch parts.

The advantages of cold stamping include the cost-effectiveness of consumables. Moreover, it increases the ability to manufacture parts that will absolutely match each other, and high production efficiency.

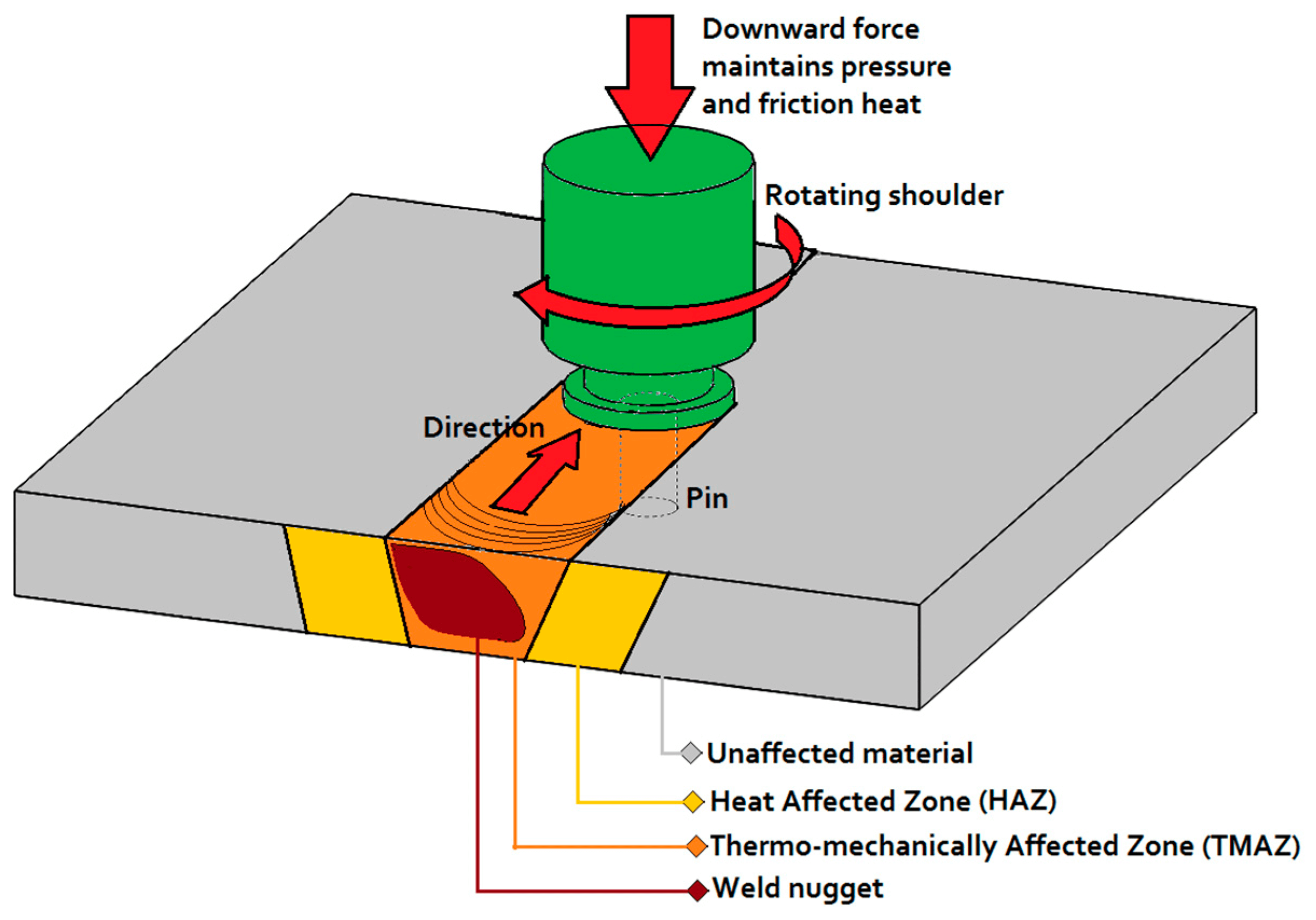

Auto Stamping Parts is a technological process that we use to produce metal sheets up to 4 mm in volume. Moreover, during operation, the material is subjected to high heating. And then special machines carry the process.

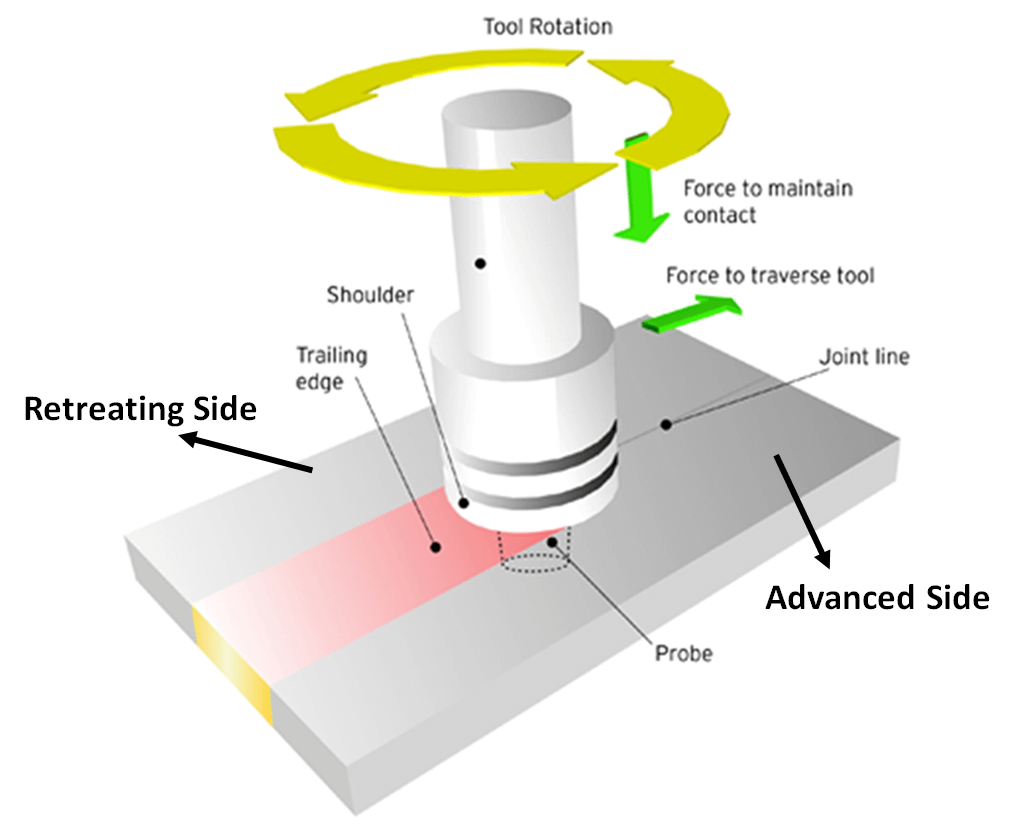

How does Auto Stamping work?

Automatic metal stamping according to customer's drawings allows you to create products of original configuration and shape in a single version and multi-batch. Thanks to automatic stamping, the parts are exactly the same. Similarly, the error can be a maximum of 0.05 mm.

Technological processes of metal stamping:

- The two pieces of sheet metal work in a straight or curved line.

- Notching. Subsequently, notches and cuts work on the metal without disturbing the overall integrity of the sheet.

- Simultaneously, the process is designed to work with the edges of the sheet. In addition, we peel off and waste the unnecessary parts.

- Punching. Auto Stamping Partsprocess with one or more holes. Hence, a pattern or pattern appears.

- Cutting down. A closed loop is made inside the metal blank and a whole fragment is removed along it. In this case, the entire part remains closed.

- It is a decorative element that allows you to correct irregularities in the metal sheet and smooth the ends.

- Cones appear on the metal surface, in other words, breaks, but without cutting off the metal layer.

How much Auto Stamping Parts Cost?

The most frequently asked and popular question: "How much does a stamped part cost?"

To calculate the cost of manufacturing, you need to add the following components:

- material cost + shipping cost / useful output (pcs),

- cost of design documentation + cost of a stamp + cost of commissioning / estimated life of a stamp,

- Cost of medium and minor repair of a stamp + cost of spare parts. Moreover, it also includes / number of parts produced from service to service,

- Moreover, Shift cost / production rate.

- Information for customers

- Generally, mass production of metal products requires technology, raw materials, equipment and tooling.

- a) Technology - we will develop,

- b) raw materials - we will purchase,

- c) equipment - in stock,

- d) equipment - we will design and order.

- We work using your tooling and can make our own.

Technology development of auto stamping

This is the very first stage of Auto Stamping Parts. Furthermore, here the cost of the part depends. At this stage, you need to clearly understand your monthly need. Based on many years of experience, we will develop the most optimal manufacturing technology for the parts you need according to the criteria "need - terms - price - quality".

At the moment, for cold stamping of parts, you can select the required steel grade: cold-rolled, hot-rolled, cold-worked, stainless, etc. Moreover, there is cretion of waste during the production of steel products. Unlike foundries, this waste cannot be recycled locally and must be disposed of. Therefore, we include the costs of disposal in the price of the products.

- Metal waste from production can range from 3 to 80%.

- Material selection - steel grade Material selection - steel grade

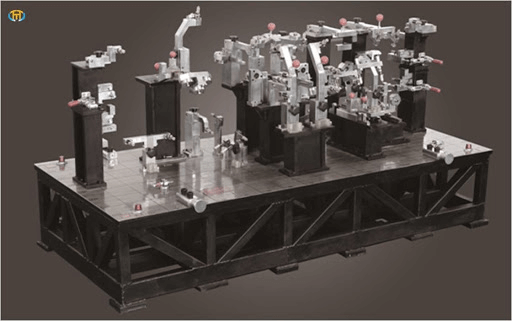

Equipment selection for Auto Stamping Parts

For the production of products based on the technology, equipment is selected taking into account:

- the steel grade

- the size of the workpiece

- the permissible force of the forging and

- Pressing equipment and the size of the finished product.

Production of documentation

For the manufacture of dies, design documentation is required - drawings. Similarly, the term for the development of design documentation is 3-4 weeks. The cost of a set of drawings for a stamp depends on the project.

Moreover, the development of design documentation is an important process. Therefore, we recommend checking cost of the forming equipment.

Tooling (stamp) manufacturing

For the manufacture of tooling (stamp), it is enough for us to receive a drawing or a sample of the part from you. Furthermore, you can allocate the cost of Auto Stamping Parts. For the manufacture of large batches of products on an ongoing basis, it is necessary to have at least two sets of dies. Subsequently, it is in order to ensure the required volumes of products. Moreover, it is to exclude downtime in the event of their breakdown.

How to even approximately understand the cost of Auto Stamping Parts?

Generally, the more complex the part, the larger the holes in it, the larger its size - the higher the cost of the stamp.

In addition, the term for making a stamp is from 1 month, the term for debugging a stamp is up to 2 weeks

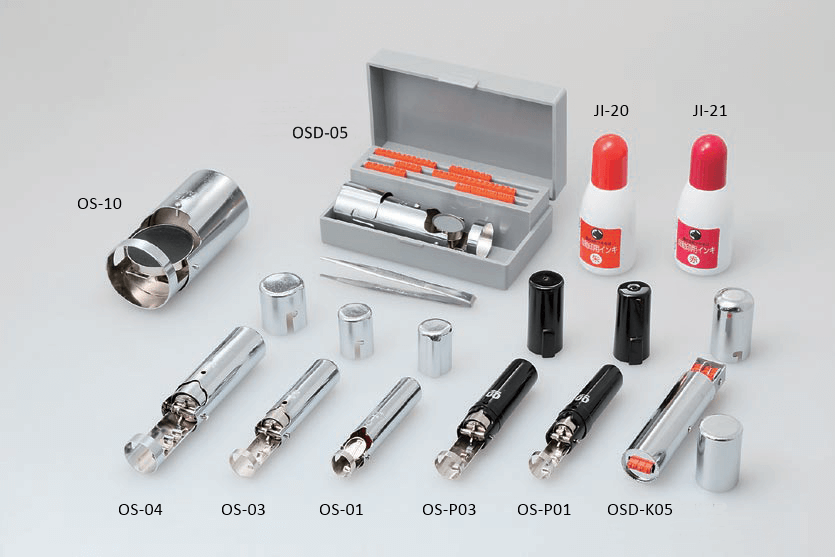

Service stamps

Stamps are equipment that undergoes a high operational load and require regular maintenance:

- Inspection

- replacement of parts

Generally, small and medium repair of dies is done according to operating time and if necessary. The Auto Stamping Parts production facility carries on-site operations. Similarly, it includes:

- disassembly

- fault finding

- replacement of wear parts

- sharpening of cutting surfaces

- demagnetization and assembly

Advantages of Descartes punching scanner-positioner

Improving punching efficiency:

- reduction in the cost of procurement

- Moreover, it increases in productivity (maximum positioning speed 50,000 mm / min).

Saving material:

- 5 times more parts from one metal volume,

- Hence, reduction of waste by 2.5 times,

- The possibility of stamping from illiquid blanks.

Savings on wages up to 9 times:

- One person can serve 3 presses.

Reducing the price of stamps by 30%:

- Moreover, you can use 2-column and non-column dies,

- Stamps without guides, stepping knives and catchers.

Occupational Safety and Health:

- The presence of a person directly near the press is not required.

Brief Description of Auto Stamping Parts Scanner-Positioner Assemblies

- High strength frame

Auto Stamping Parts includes the high-strength, full-size frame. Similarly, it comes with high-tech welding. Moreover, it can withstand loads of up to 63 tons, ensuring stable and reliable operation.

Stamp frame Descartes Stamp frame Descartes

- Technology of compensation of unevenness of the workpiece

Generally, the roller can freely follow the curvature of the sheet surface. To compensate for unevenness of the sheet during travel, the drive rollers have a vertical stroke.